Facing is a lathe machining operation in which material is removed from a workpiece’s end using a particular tool. It produces a smooth surface perpendicular to the rotation axis of the workpiece. In machining, facing can be used in two different ways: on a milling machine and on a lathe.

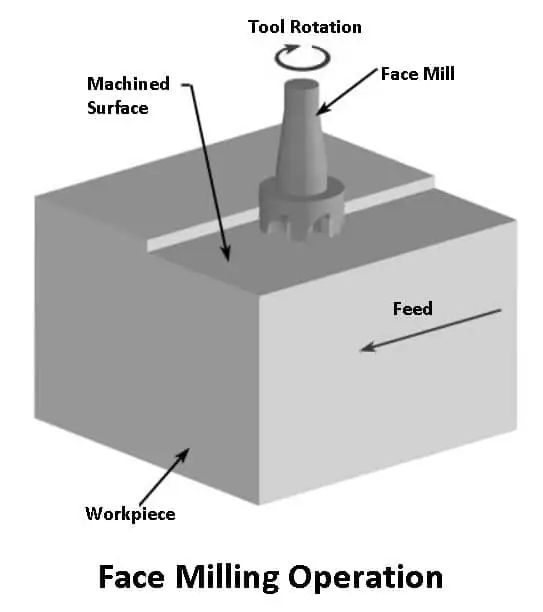

The facing operation on a milling machine includes various milling operations but mainly considers face milling. Whereas in lathe machines, facing operation is generally used in turning and boring operations.

Let’s understand the facing operation in detail below.

Read Also: What is Turning Operation? [Definition, Types & Procedure]

Facing Operation on Lathe

When performing a facing operation on a lathe, the machinist uses a facing tool to remove a flat surface perpendicular to the workpiece’s rotational axis. A facing tool is usually mounted in a tool holder that is installed on the lathe machine.

The facing tool is then fed perpendicularly across the axis to the workpiece. The machinist will have the option of using hand feed or power feed option in the machine. To obtain a smooth surface, it is optimal to use the power feed option due to the constant feed rate.

By facing, the workpiece will be cut to its finished length very precisely. Depending on how much material must be removed from the workpiece, a machinist may take roughing or finishing cuts.

Many factors can affect the quality and performance of facing operations in lathe machines, including:

Read more: FACING OPERATION