Capabilities

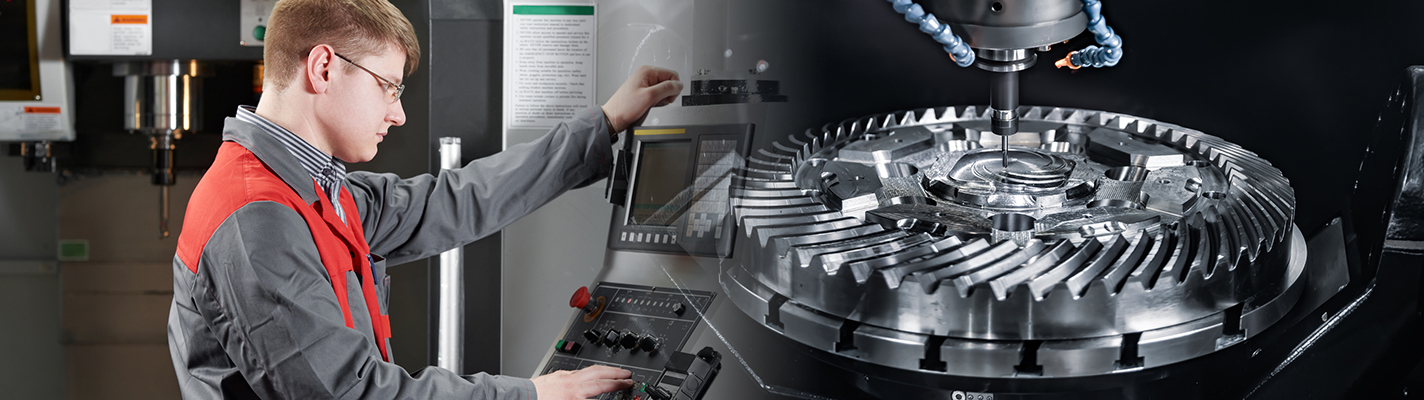

What Makes Toolcraft Unique?

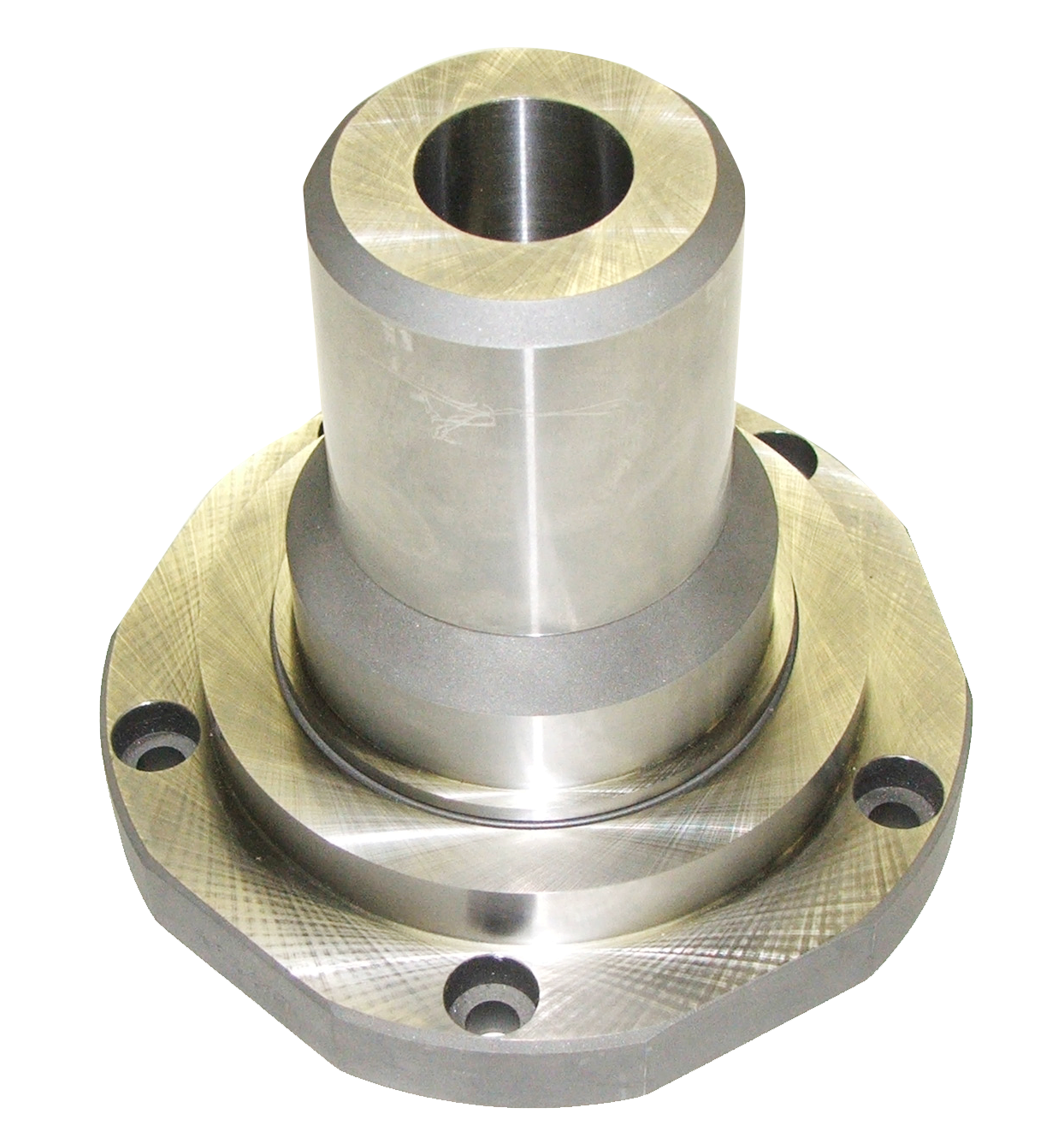

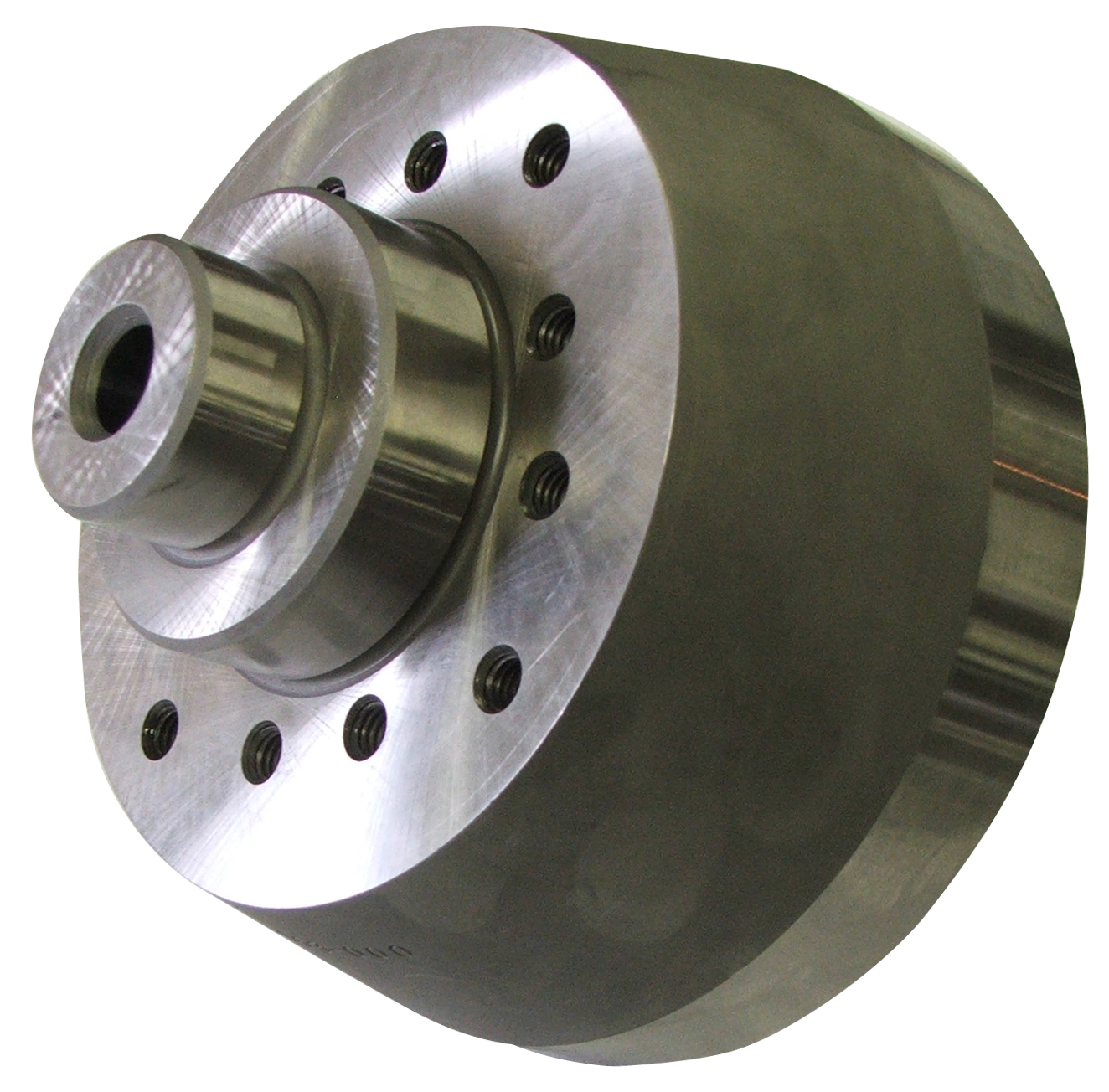

Specialists in

Close Tolerance

Machining

Close Tolerance

Machining

Inspection Reports

Provided With

Every Job

Provided With

Every Job

Experienced

Journeymen

Toolmakers

Journeymen

Toolmakers

Delivery On Time,

Every Time!

Every Time!

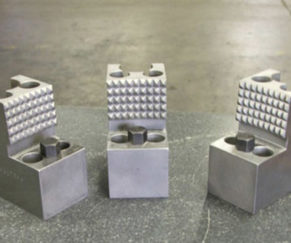

Project Showcase

Industry News

Toolcraft: Optimizing the Perspective on Cylindrical OD Plunge Grinding

In the realm of cylindrical OD plunge grinding, there are opportunities to optimize parameters without[...]

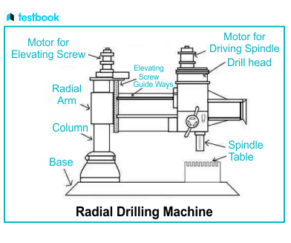

Toolcraft: Unveiling the Diversity of Drilling Machines – A Comprehensive Analysis

As highlighted by Market Prospects in their article "What Types of Drilling Machines Exist and What Are[...]

Toolcraft: Mastering Precision Explores Radial Drilling Machine Technology

In the comprehensive guide "Radial Drilling Machine: Learn Diagram, Parts, Working, Advantages and[...]