Machining a Casting to Make a Flanged Inlet for Chemical Pumps

Machining a Casting to Make a Flanged Inlet for Chemical Pumps

Customer

Chemical Pumps Company in NE Indiana

Products/Service

Machining a casting to make a Flanged Inlet for Chemical Pumps

Customer Requirements

Customer was having trouble with delivery and quality from an existing supplier.

Solution

Toolcraft installed a dedicated Robotic Machining Cell that picks castings from a drawer and loads & unloads 2 Okuma Lathes. Each Lathe has a sub-spindle and live tooling to produce a finished part. To keep up with the demand of 650 pieces per day two lathes were required. Toolcraft is able to run approximately 700-800 parts in a 10 hour shift.

Customer Value Gained

Customer is now receiving the quality and delivery as required.

Quality Verification

Initial PPAP was required to insure the consistency and quality of the parts. Quality checks with hard gages are used in the production process.

Industry News

Toolcraft: Optimizing the Perspective on Cylindrical OD Plunge Grinding

In the realm of cylindrical OD plunge grinding, there are opportunities to optimize parameters without[...]

Toolcraft: Unveiling the Diversity of Drilling Machines – A Comprehensive Analysis

As highlighted by Market Prospects in their article "What Types of Drilling Machines Exist and What Are[...]

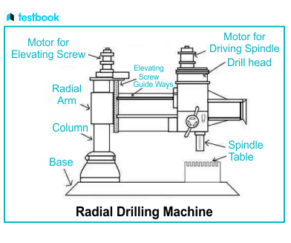

Toolcraft: Mastering Precision Explores Radial Drilling Machine Technology

In the comprehensive guide "Radial Drilling Machine: Learn Diagram, Parts, Working, Advantages and[...]