Custom Broach Tooling for Gear Manufacturing

Custom Broach Tooling – S. Carolina

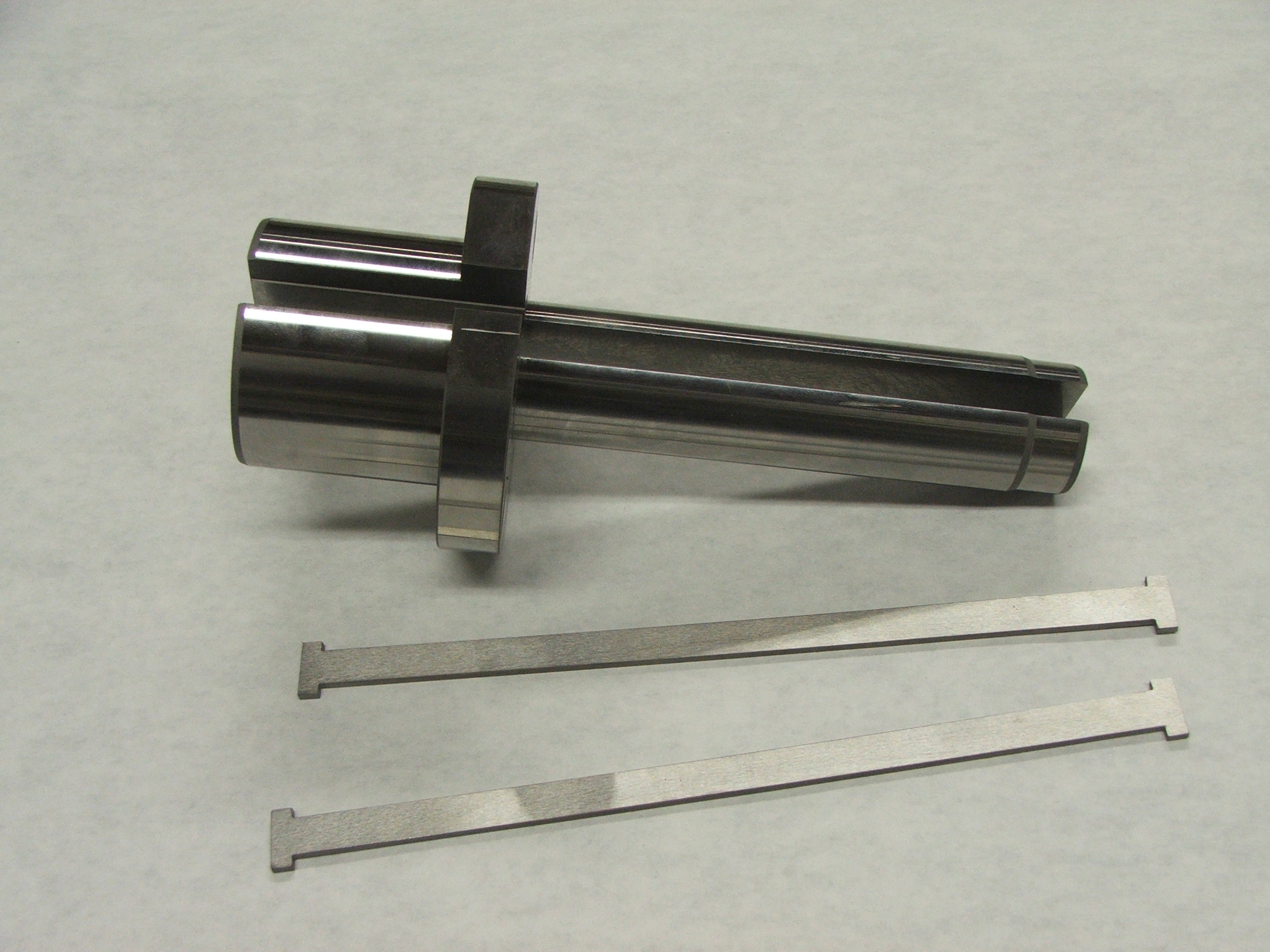

For over half a century at Toolcraft, LLC the expert craftsmanship of our toolmakers has been elevating the industry standard for precision broach tooling. We fabricated the tool set highlighted here for a customer in the gear manufacturing industry who knew they could rely on us for a superior product and great service.

Used to manufacture large gears, this set of tooling included a broach horn with dimensions of 6.0″ in diameter x 16.0″ in length, which we fabricated from 8620 steel to provide high surface wear resistance. We fabricated the two 1.5″ wide x 18.0″ long shims, one measuring 0.250″ in thickness, the other 0.187″ from tough A2 steel for maximum dimensional stability during heat treatment.

- CNC Turning

- CNC Milling

- Surface Grinding

- Cylindrical Grinding

- Lathe, Mill, Surface Grinder, Cylindrical Grinder

- 6″ Dia x 16″ Long

.250″ Thick x 1.500″ x 18″ Long

.187″ Thick x 1.500″ x 18″ Long

- +/-.0002″

Capabilities Applied/Processes

Primary operations consisted of CNC turning and milling to create the part features and geometries. The parts were then case hardened to RC 58-60. The talents of our journeymen grinders were required to hold these components to within tight +/-.0002″ dimensional tolerances.

Delivery/Turnaround Time

We delivered the tooling to the customer within a 4 week timeframe, where it is now helping them yield high production rates and manufacture the best possible product. Our commitment to excellence is why we achieved a long standing relationship with this client and continue to do many projects for them.

| Material Used | 8620 Steel, Case Hardened 1/32″ Deep, RC 58-60 A2 Steel RC 58-60 |

| Material Finish | Ground |

| Volume | 1 Broach Horn 2 Broach Shims |

| Turnaround Time | 4 Weeks |

Industry News & Blog

Precision at Its Best: Toolcraft’s Custom True Position and Hole Location Gages - At Toolcraft, precision is not just an expectation; it's our…

Toolcraft: Empowers Machining with Milling Cutter - In the realm of machining, milling cutters reign supreme as…

Precision at Every Turn: Our CNC Machining Capabilities - At Toolcraft, we pride ourselves on our comprehensive CNC machining…