Custom True Position & Hole Location Gages

Custom True Position & Hole

Location Gages

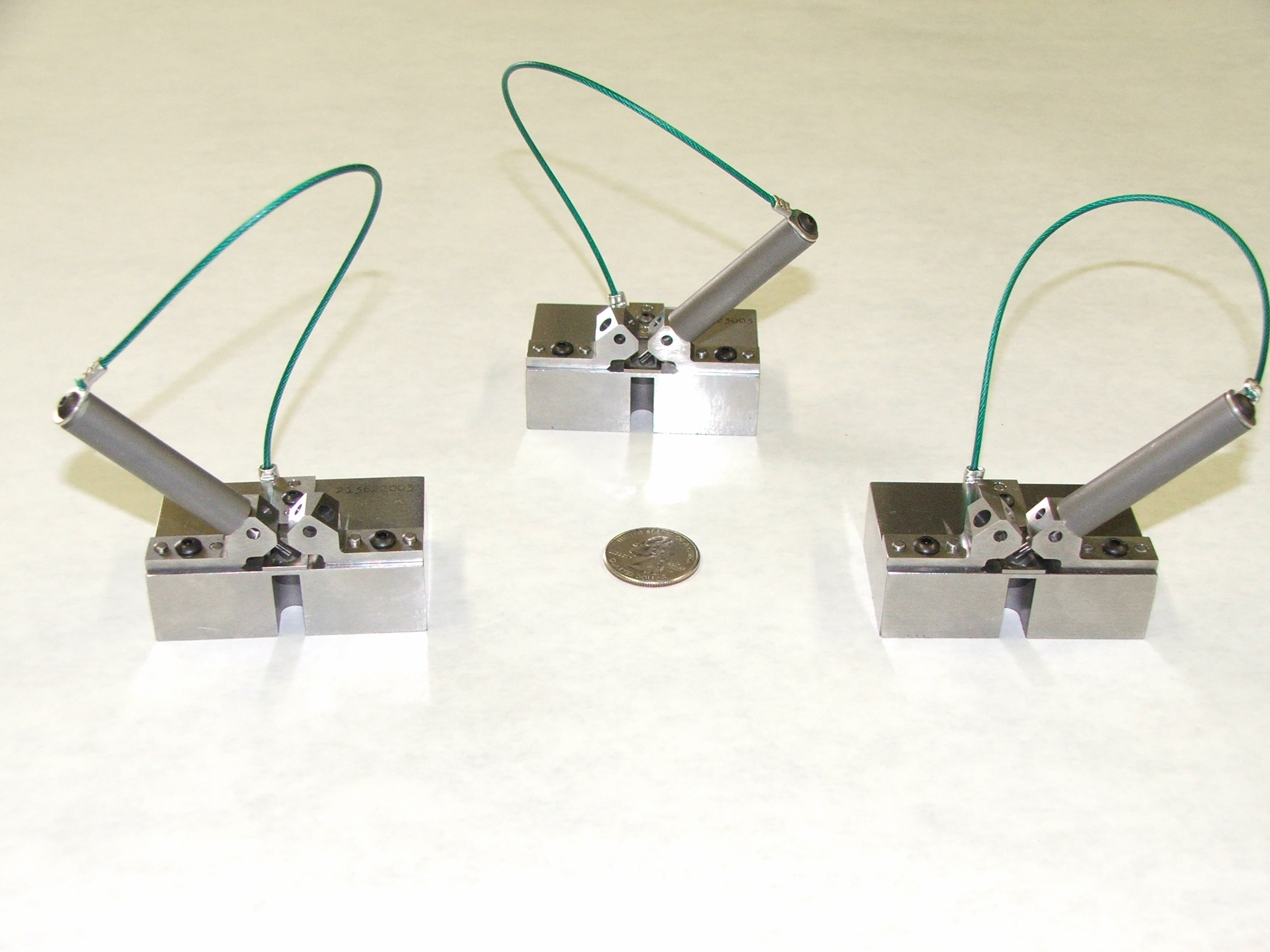

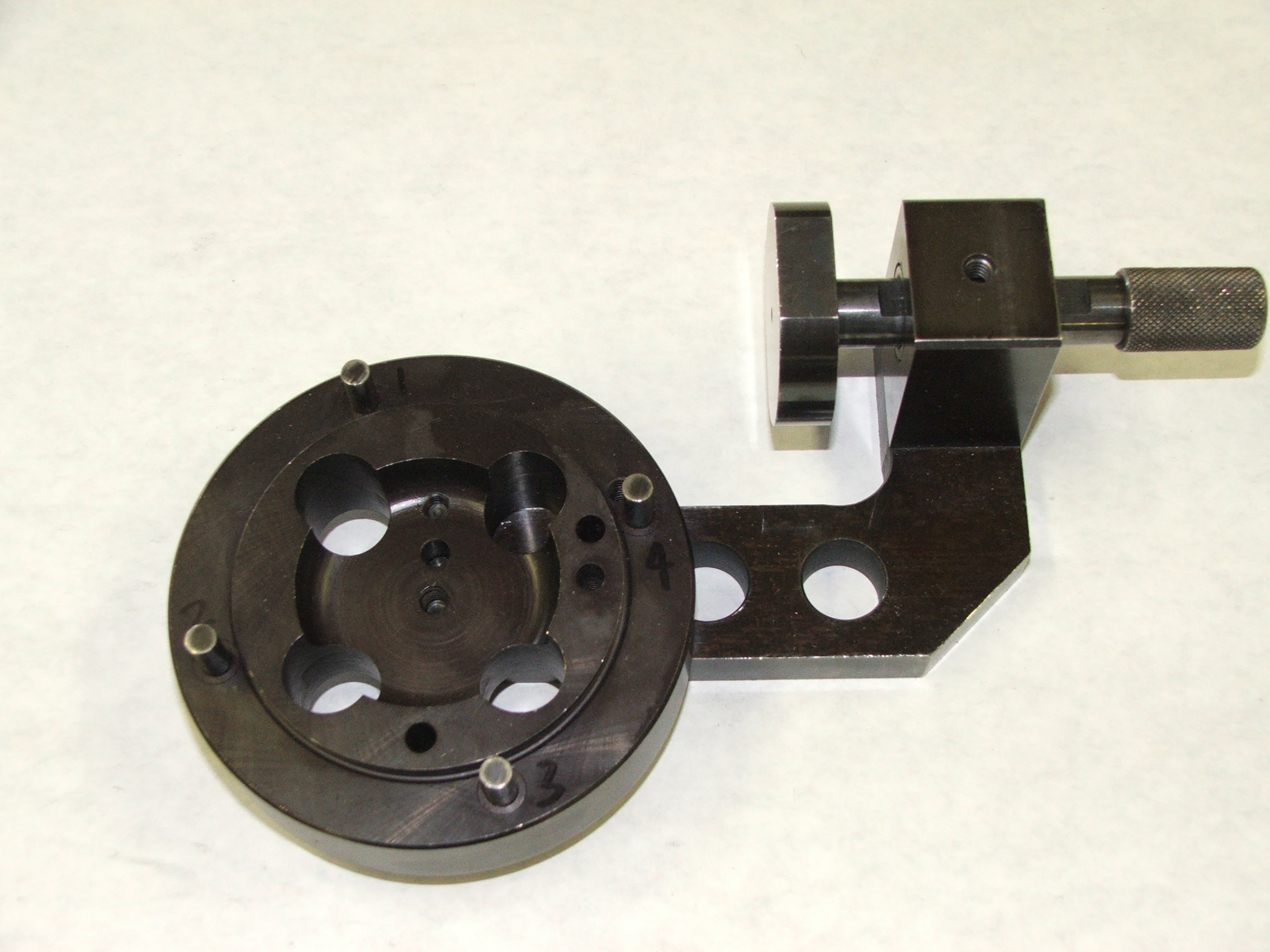

At Toolcraft, LLC our experienced journeymen toolmakers are capable of creating precision custom true position and hole location gages to meet demanding customer specifications. As experienced toolmakers who routinely hold dimensional tolerances on the order of +/-0.0001″, we have developed a reputation for providing precision machining of very complex parts. Customers in a wide variety of industries trust us to fabricate the custom tooling, fixtures, and gages that allow them to produce accurate, repeatable parts.

Gages can be produced from most any metal, with tool steel alloys being the most common. A large inventory of raw material is kept on hand to shorten lead times. Precision metrology instrumentation including optical comparators, certified gage blocks, and a Brown & Sharpe Micro-Hite are all used to verify dimensions. A complete inspection report is provided with every project, detailing all dimensional inspection and testing performed.

We can open most major CAD file formats and verify prints for manufacturability before fabrication. The typical lead time for a project is 4 weeks depending on complexity and

material availability, but every effort is made to

accommodate specific customer needs.

For more information about our custom true position and hole location gages, see the content below, or contact us directly.

| Accuracy | +/-0.0001″ |

| Inspection | Optical Comparators Brown & Sharpe Micro-Hite Toolmaker’s Micrometer Dial Indicators Certified Gage Blocks |

| Production Volume | Single Piece Specialty Production Low Volume High Volume |

| Lead Time | 4 Weeks Typical |

Custom True Position & Hole Location Gages Capabilities

Repair

Modification

Calibration

True Position

Hole Location

Length

Flush Pin

Run Out Arbors

Inspection

Tool Steel

Stainless Steel

Aluminum

Low Carbon

Industry Focus

File Formats

Most Major CAD Formats

Industry News & Blog

Precision at Its Best: Toolcraft’s Custom True Position and Hole Location Gages - At Toolcraft, precision is not just an expectation; it's our…

Toolcraft: Empowers Machining with Milling Cutter - In the realm of machining, milling cutters reign supreme as…

Precision at Every Turn: Our CNC Machining Capabilities - At Toolcraft, we pride ourselves on our comprehensive CNC machining…