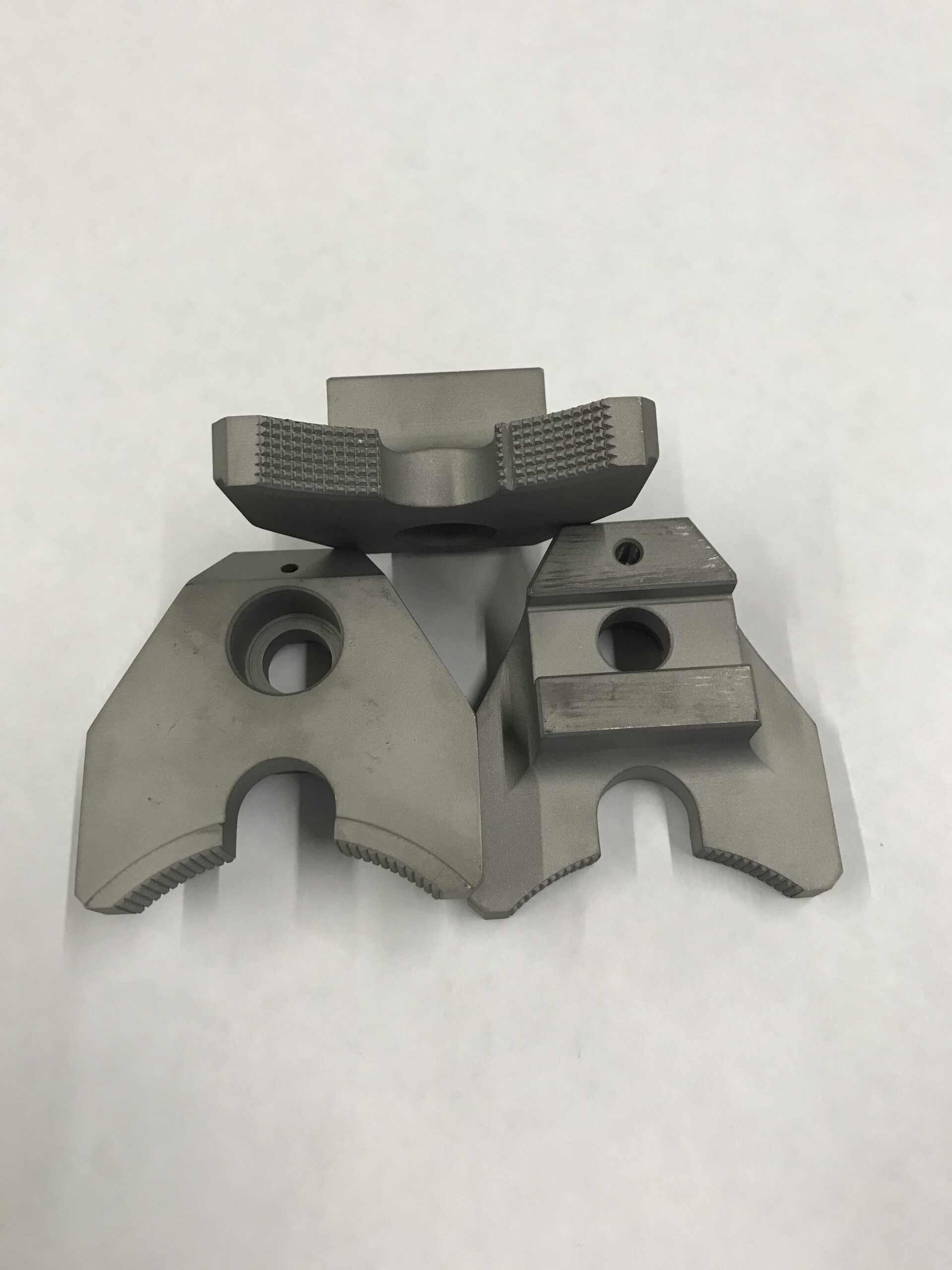

Custom Chuck Jaws for Gear Manufacturing

Custom Chuck Jaws – Tennessee

- CNC Milling

- CNC Lathe

- Shaping Attachment

- Lathe, Mill

Capabilities Applied/Processes

Primary operation consisted of CNC Milling, CNC Lathe and Bridgeport Mill with a Shaping Attachment.

Everything was milled to size so grinding was not required.

Parts ended up being Black Oxided (not shown in picture)

Delivery/Turnaround Time

Quantity is 14 pieces with delivery of 4 weeks.

| Material Used | 8620 Steel Case Hardened 1/32″ Deep RC58-60 |

| Volume | 14 |

| Turnaround Time | 4 Weeks |

To learn more about this project, or for a quote on an upcoming tooling requirement, contact us today.

Industry News & Blog

Precision at Its Best: Toolcraft’s Custom True Position and Hole Location Gages - At Toolcraft, precision is not just an expectation; it's our…

Toolcraft: Empowers Machining with Milling Cutter - In the realm of machining, milling cutters reign supreme as…

Precision at Every Turn: Our CNC Machining Capabilities - At Toolcraft, we pride ourselves on our comprehensive CNC machining…