Custom Fixturing

Custom Fixturing

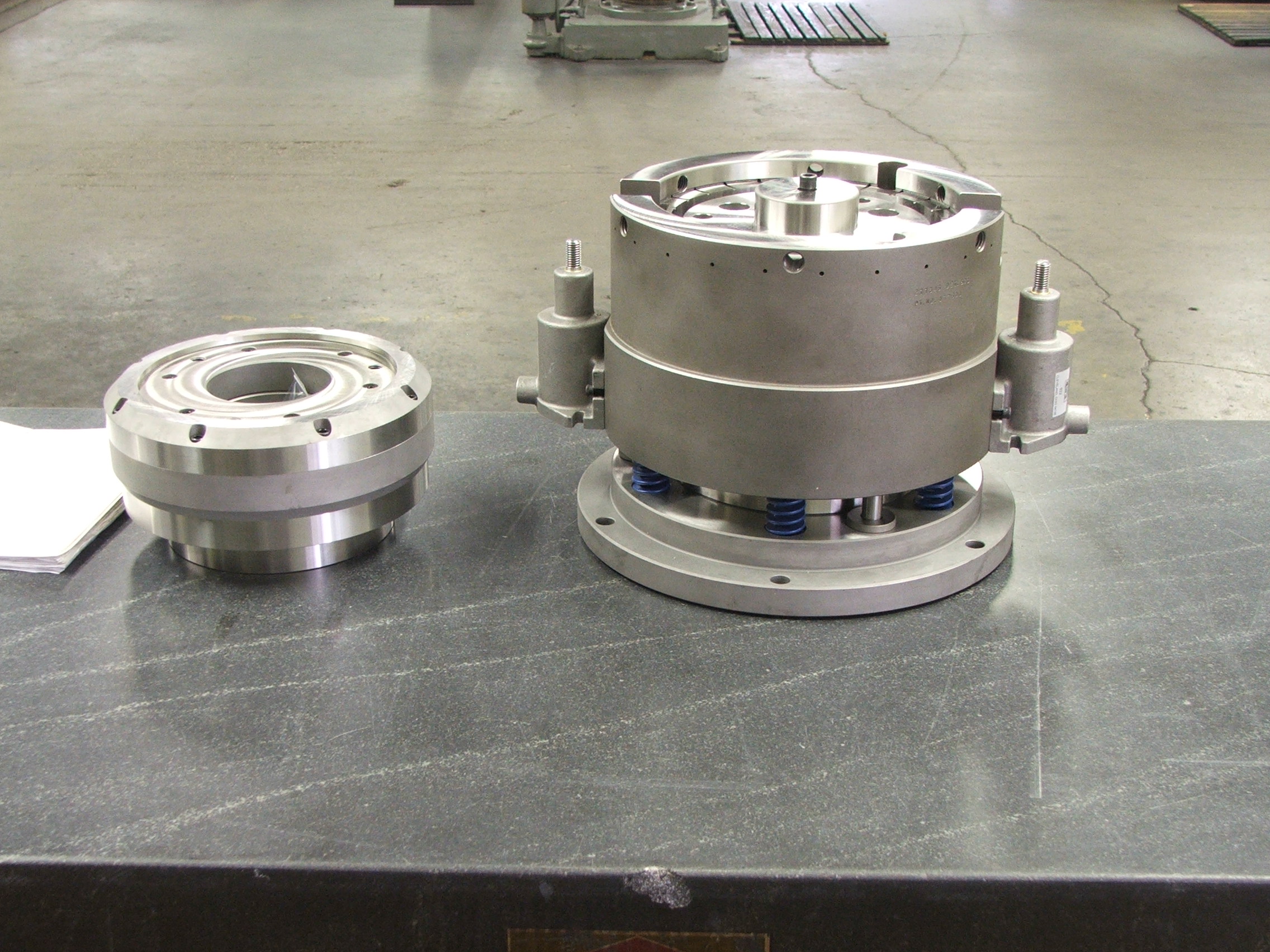

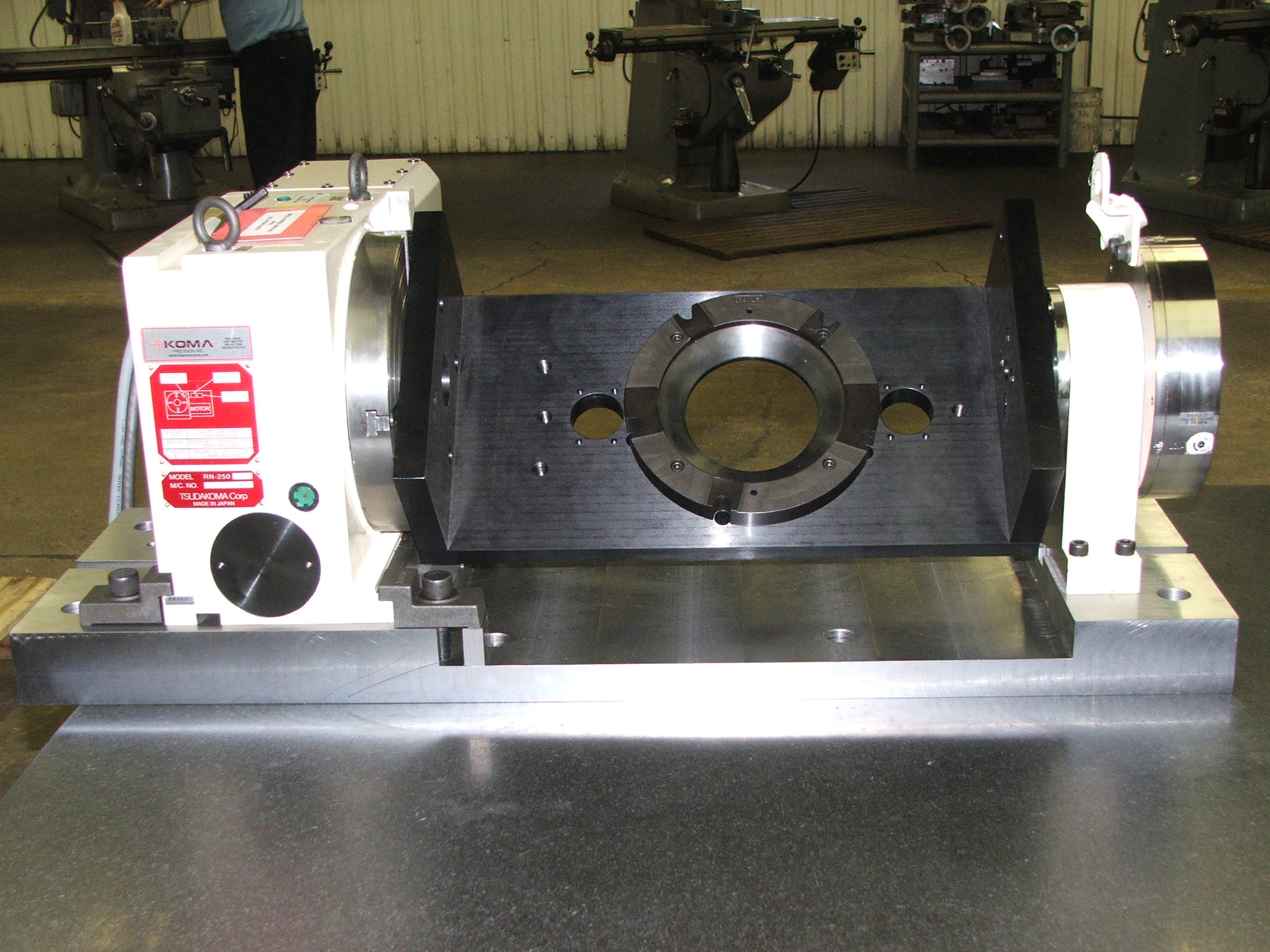

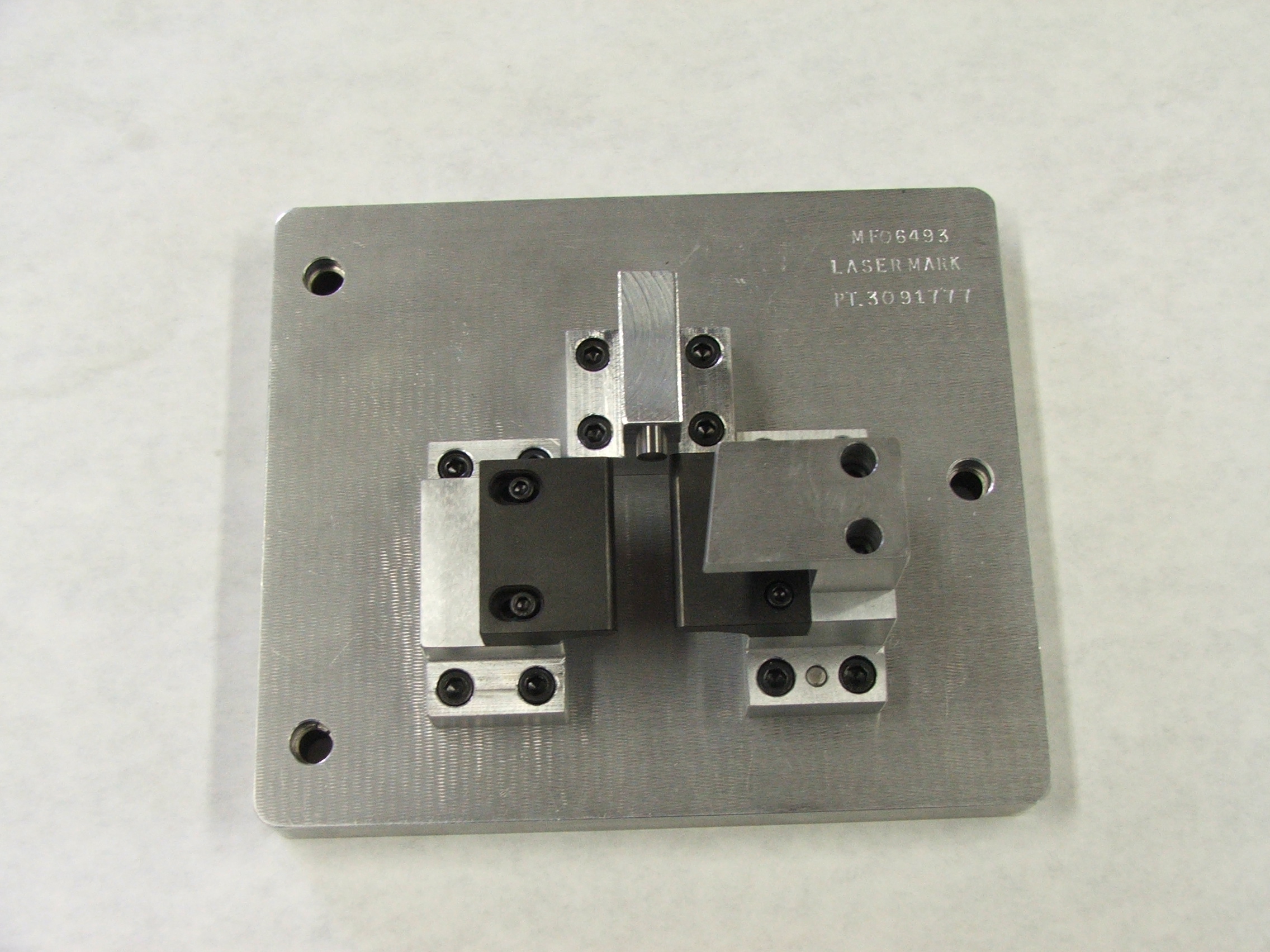

As a precision custom fixturing manufacturer, at Toolcraft, LLC we serve the most advanced manufacturing industries including automotive, and medical device customers. We are capable of machining and building new manual or semi-automatic fixtures to print as well as reverse engineering physical fixtures. We accept most major CAD formats and verify all prints before machining to ensure that designs are optimized for manufacturability. Custom fixturing types include workholding and inspection fixtures as well as chuck jaws. Existing fixtures can be modified, repaired, or calibrated to customer specifications. Most any material can be used depending on the specific application, with a large inventory of in-stock steel available for immediate machining.

Our journeymen toolmakers are capable of holding dimensional tolerances of +/-0.0001″ or less as required. Certified gage blocks are used to accurately measure lengths and our Brown & Sharpe Micro-Hite is capable of verifying complex dimensions. Complete inspection reports are provided with each fixture. If fixtures ever need calibration or modifications, they can be returned to us for additional service. The typical turnaround time for a custom project is approximately four weeks. For more information about our custom fixturing capabilities, see the table below, or contact us directly.

Custom Fixturing Capabilities

New Fixture Fabrication

Repair

Modification

Calibration

Reverse Engineering

Drilling

Welding

Grinding

Machining

Inspection

Workholding

Jaws

Chucks

Manual

Semi-Automatic

Tool Steel

Stainless Steel

Aluminum

Low Carbon

+/-0.0001″

Optical Comparators

Brown & Sharpe Micro-Hite

Toolmaker’s Micrometer

Dial Indicators

Certified Gage Blocks

Single Piece Specialty Production

Low Volume

High Volume

4 Weeks Typical

Industry Focus

File Formats

Most Major CAD Formats

Industry News & Blog

Precision at Its Best: Toolcraft’s Custom True Position and Hole Location Gages - At Toolcraft, precision is not just an expectation; it's our…

Toolcraft: Empowers Machining with Milling Cutter - In the realm of machining, milling cutters reign supreme as…

Precision at Every Turn: Our CNC Machining Capabilities - At Toolcraft, we pride ourselves on our comprehensive CNC machining…