Custom Precision Tooling

Custom Precision Tooling

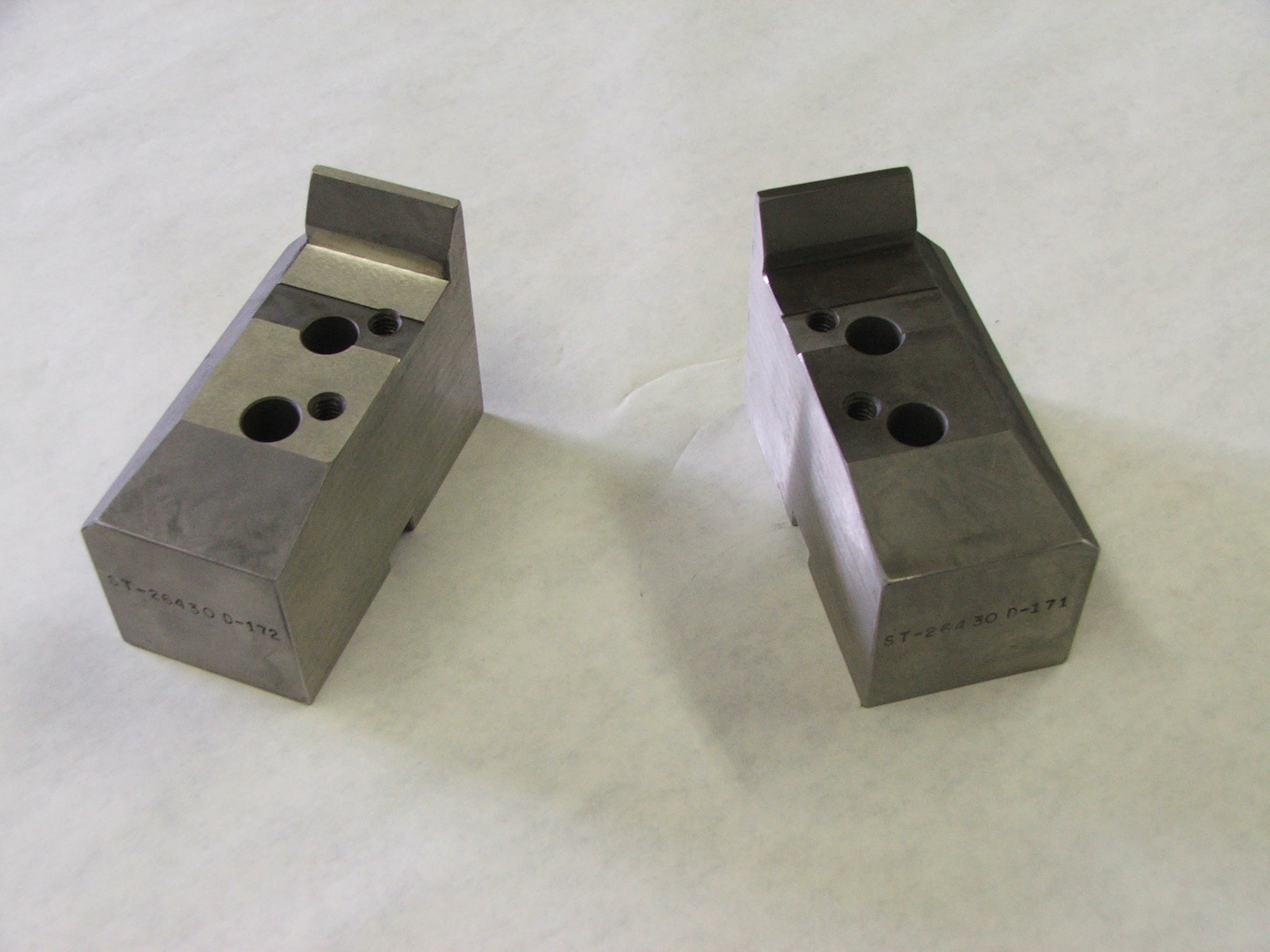

The custom precision tooling we produce at Toolcraft, LLC is used in the automotive, medical equipment, food service, and other advanced manufacturing industries. Our capabilities include the production of new tooling as well as repair, modification, and calibration of existing tooling. Tooling such as collets, hob arbors, and gage masters are produced by experienced toolmakers using advanced CNC equipment. Our journeymen toolmakers routinely hold dimensional tolerances of +/-0.0001″ on complex geometries.

A large inventory of steel is kept in stock to minimize customer lead time. After a final drawing is submitted, most projects are completed within four weeks. Many customers collaborate with us during the final stages of the design process to ensure that their tooling is optimized for manufacturing and end use. In addition to machining to print, we can take broken or worn existing tooling and reverse engineer replacement parts.

Complete inspection reports are provided with each project, verifying all critical dimensions. Multiple inspection tools including Micro-Hite equipment, dial gages, and toolmaker’s micrometers are used to ensure that all dimensions are to customer specifications. For more information about our custom precision tooling, see the table below, or contact us directly.

Custom Precision Tooling Capabilities

New Gage Fabrication

Repair

Modification

Calibration

Collets

Hob Arbors

Inspection Arbors

Gage Masters

Keyway Gages

Broach Horns

Tool Steel

+/-0.0001″

Optical Comparators

Brown & Sharpe Micro-Hite

Toolmaker’s Micrometers

Dial Indicators

Certified Gage Blocks

Single Piece Specialty Production

Low Volume

High Volume

4 Weeks Typical

Industry Focus

File Formats

Most Major CAD Formats

Industry News & Blog

Precision at Its Best: Toolcraft’s Custom True Position and Hole Location Gages - At Toolcraft, precision is not just an expectation; it's our…

Toolcraft: Empowers Machining with Milling Cutter - In the realm of machining, milling cutters reign supreme as…

Precision at Every Turn: Our CNC Machining Capabilities - At Toolcraft, we pride ourselves on our comprehensive CNC machining…