Capabilities

What Makes Toolcraft Unique?

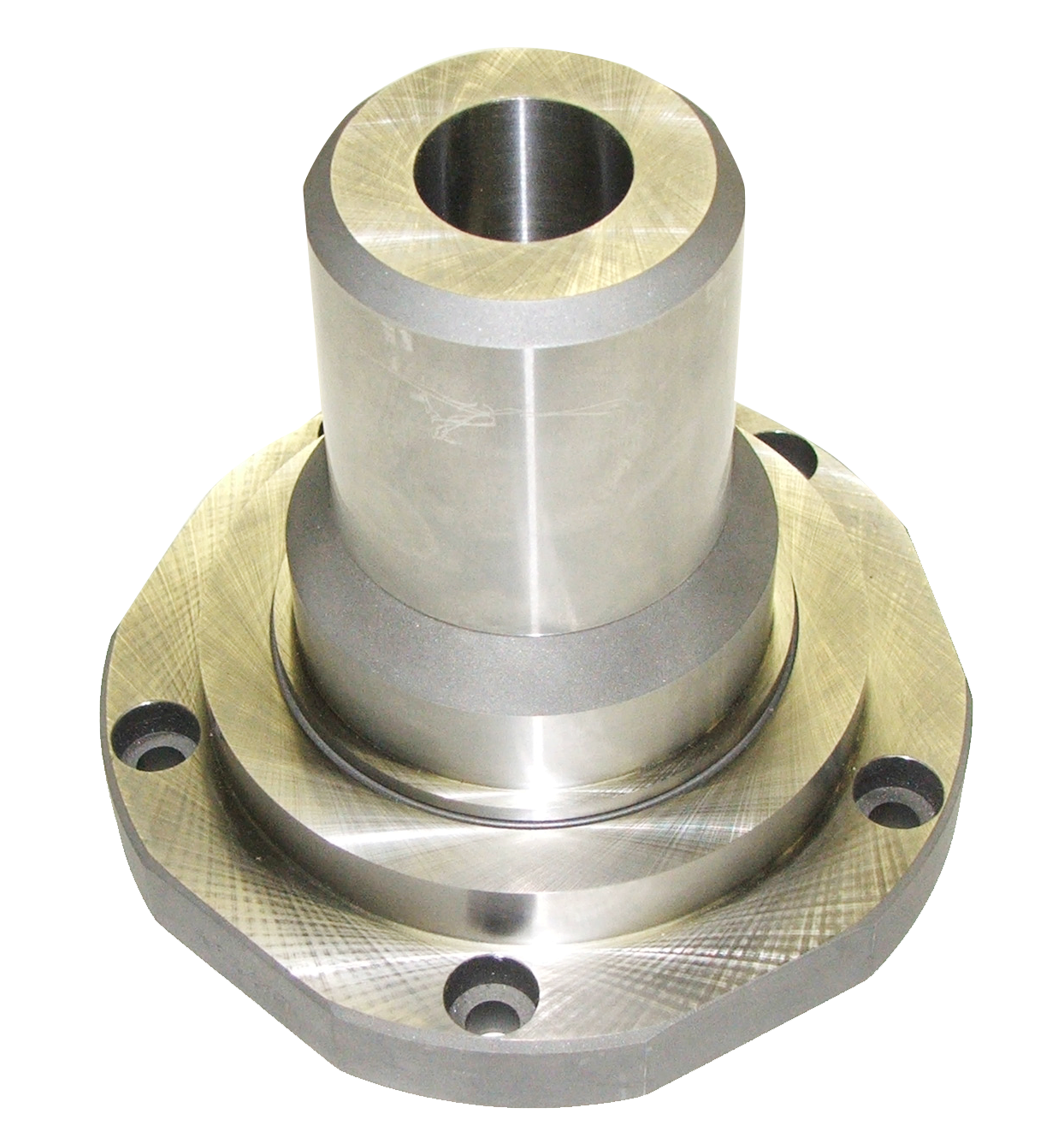

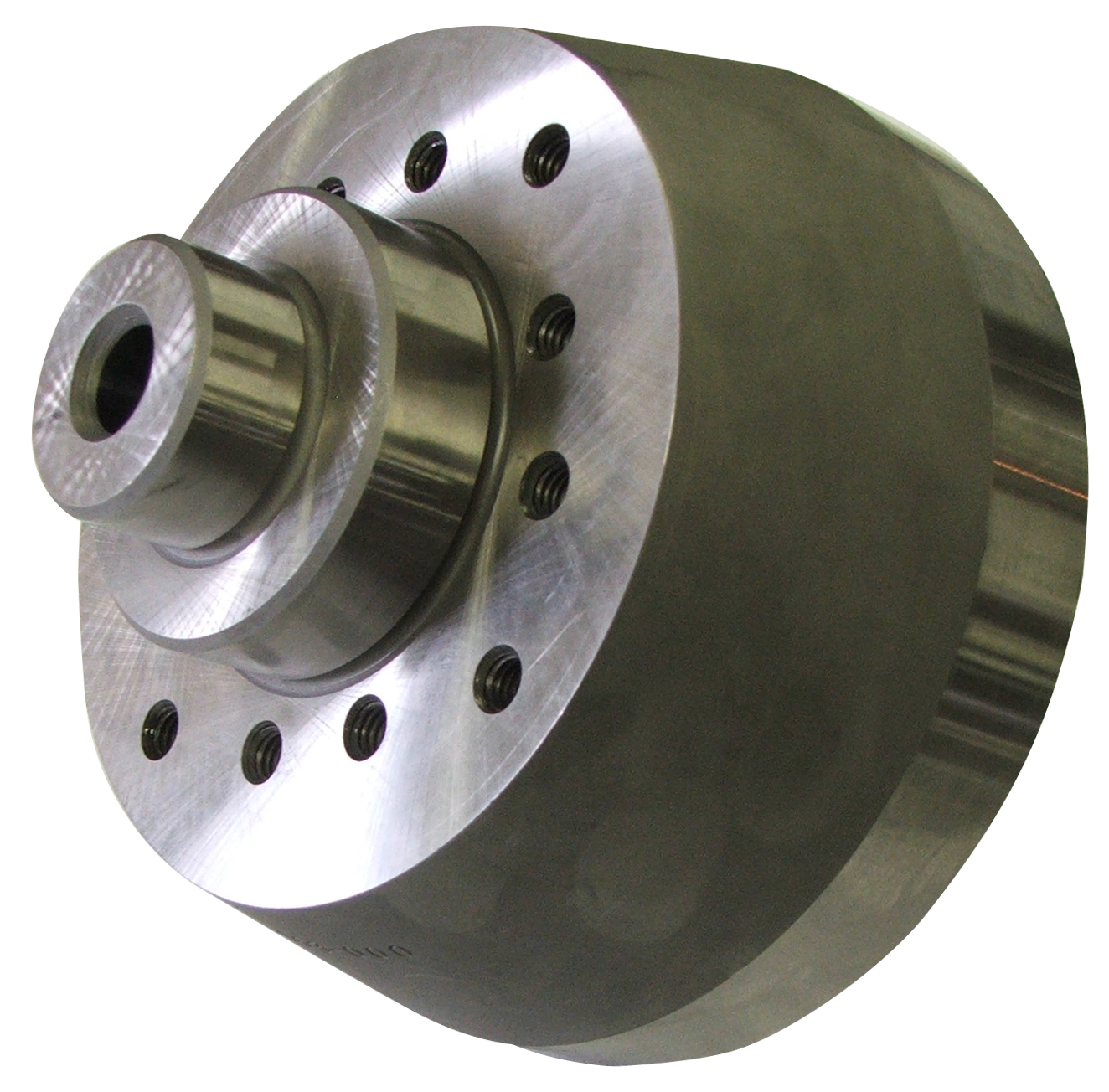

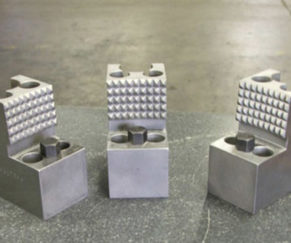

Specialists in

Close Tolerance

Machining

Close Tolerance

Machining

Inspection Reports

Provided With

Every Job

Provided With

Every Job

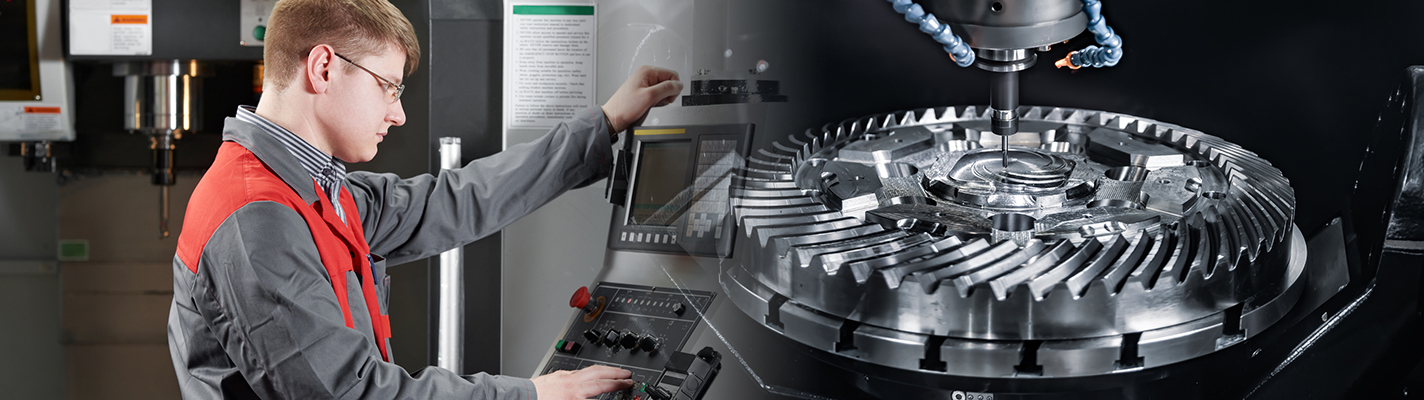

Experienced

Journeymen

Toolmakers

Journeymen

Toolmakers

Delivery On Time,

Every Time!

Every Time!

Project Showcase

Industry News

No post found