A new reality is emerging in precision machining. Technology is evolving. Demand for customization is growing. Lead time are becoming shorter. And tolerances are tightening. But over the next decade, manufacturing is poised to experience the biggest (and fastest) transformation since the Industrial Revolution.

Momentum within the space has been mounting since the early 2000s; but the spark to the powder keg occurred in 2020: the COVID-19 pandemic.

The COVID-19 pandemic has fundamentally altered the way we live, work, and relate to one another. For the precision machining industry, the pandemic has drastically impacted businesses and operations, and the effects will last.

Here are key trends on the horizon that will completely change the direction of precision machining in the next 10 years.

1. Automation will become indispensable

Although increasing automation has long been a trend within precision machining and manufacturing, the pandemic exposed the high cost of unforeseen disruptions in production. Many plants and facilities were forced to limit the number of onsite personnel for months at a time. Under these circumstances, having an operator for every machine is no longer feasible.

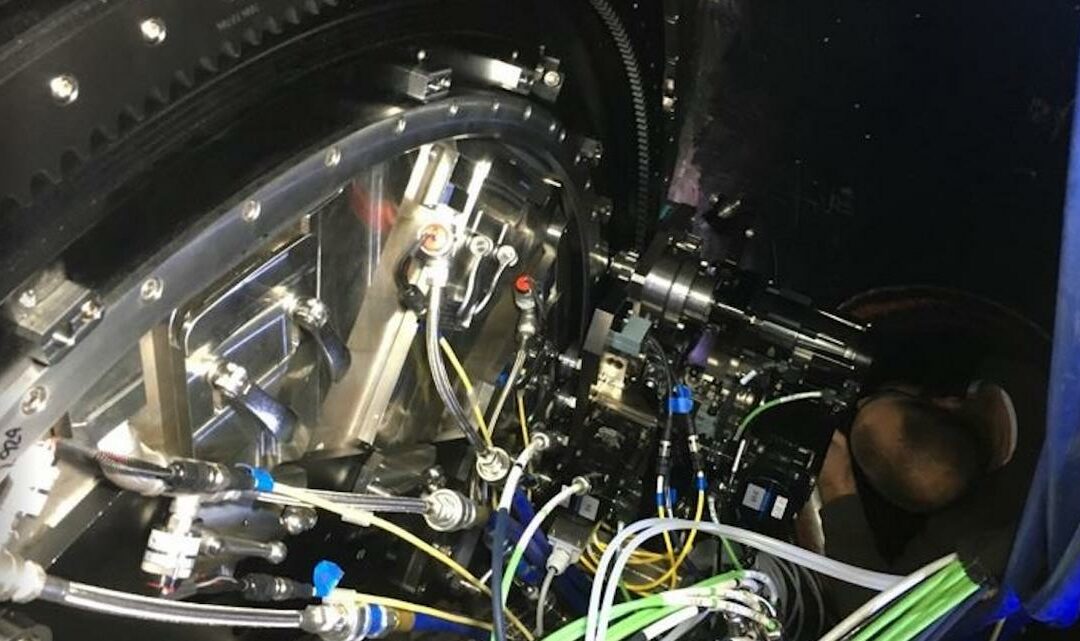

“To become adaptable in the future, companies must adopt more machines and tools with advanced automation,” says Justin Tripp, vice president of engineering at Tri Tool Technologies, a global leader in the design and manufacture of high-performance, precision machine tools and custom engineered solutions for major industrial markets. “Right now, it’s difficult to find good operators of machinery. With manufacturing on the rise, automation will help companies keep pace.”

2. The industrial Internet of Things (IIoT) will dominate emerging technology

The pandemic also underscores the value of IIoT technology in computer numerical control (CNC) machines. Through embedded sensors on CNC machines, IIoT allows for the real-time monitoring of conditions, sending alerts or notifications to operators whenever tuning or maintenance is due.

IIoT also has the potential to establish machine-to-machine synchronization, resulting in reduced manual efforts and improved worker safety. While the IoT itself is nothing new, it has only recently found its way into the precision computing of the CNC machining industry and can help making manufacturing processes faster, safer, and of higher quality.

Read more: 5 trends that will completely transform precision machining in the next decade