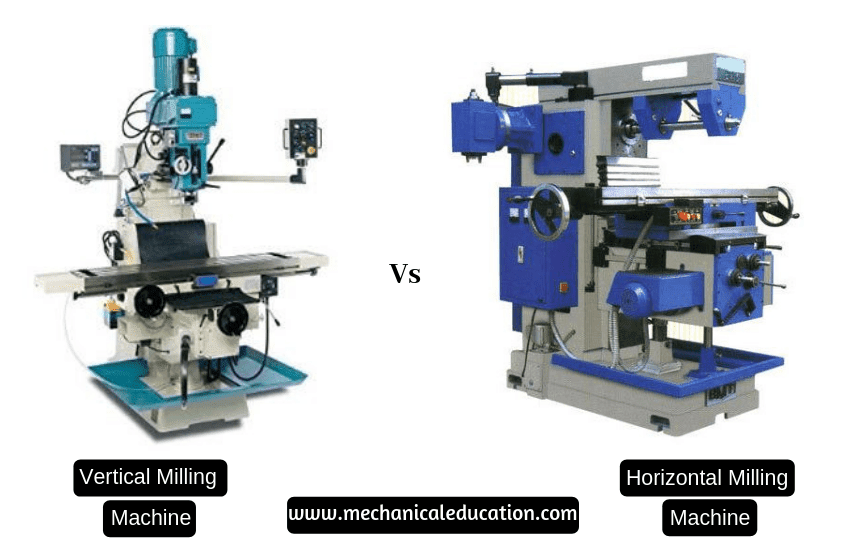

Horizontal milling machine:

-

- In this machine Cutting tool is in Horizontal position.

- Work piece is parallel to rotating spindle.

- It has a vertical column. which supports ram, motor, and arbor.

- In this machine table can move in longitudinal, vertical, and cross.

- This is used in manufacturing operations.

- It required more floor space compared to vertical.

- This machine is more costly compared to vertical.

- This can produce a refined surface finish.

- This is highly used for complex things.

- This is used for slots making, grooves, threaded mounting holes etc.

Vertical Milling machine:

- The spindle in it is a vertical position.

- Work piece is in perpendicular with the spindle.

- It has a vertical column. which carry head and sideways.

- This can be moved in upward, downward, and can be swiveled to any angle.

- This is less in cost compared to horizontal.

- In this surface finish is not as smooth as horizontal.

- It required less floor space than horizontal.

- This is used to machine grooves, flat surfaces etc.

- This is used for machining large metal plates.

Read more: Difference between horizontal and vertical milling machine