Up Milling and Down Milling:

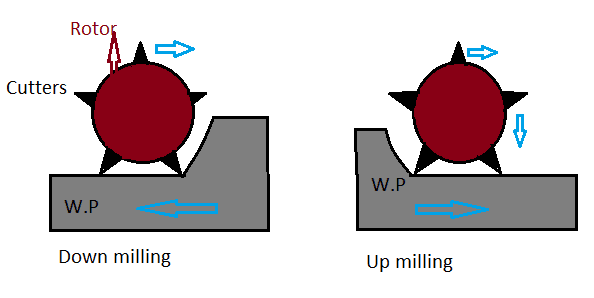

Up Milling and Down Milling: Up milling and down milling are the two different methods of cutting process in a milling operation, in both the operations work piece is used to feed towards the cutting tool for milling operation and tool used to rotate in a fixed center to remove the external surface of work, which gets feed against the cutting tool. In this type of milling operation, two different types of process are used to work on different machining operations this type of process is mainly used in surface finishing, forgining etc.Both the milling operations look like the same process but they used to cut the work in different directions according to the rotation of tool. In up milling cutting tool used to rotate in clockwise direction and in down milling cutting tool rotates in an anticlockwise direction.In this type of milling operation cutting tool undergoes to huge stresses and there is a need for additional coolant. The detailed explanation about the difference between Up milling and down milling is as follows

Difference Between Up Milling and Down Milling:

Up Milling Operation:

Up milling is also known as Conventional milling. This milling operation is used to cut the workpiece to obtain a required product.

In this milling process cutting tool used to rotate in opposite direction to the feed of workpiece. A cutting tool in up milling machine removes the extra material from the workpiece in the form of chips. and the thickness of chips gradually increases in this milling operation.

This type of milling operation is used for machining casting products and clearing the forgings.

Down Milling Operation:

Down Milling is also known as Climb milling process. This process is used to remove the external surface of the workpiece.

In down milling operation cutting tool used to rotate in the same direction to the feed of workpiece. This machining process removes the extra material from the workpiece in the form of chips but in this milling process thickness of chip decreases gradually. In this operation the workpiece should hold rigidly at work table.

This type of machining is used in surface finishing and for removing the small crakes.