Introduction to milling Operation :

The milling machine is one of the important machining operations. In this operation the workpiece is fed against a rotating cylindrical tool. The rotating tool consists of multiple cutting edges (multipoint cutting tool). Normally axis of rotation of feed given to the workpiece. Milling operation is distinguished from other machining operations on the basis of orientation between the tool axis and the feed direction, however, in other operations like drilling, turning, etc. the tool is fed in the direction parallel to the axis of rotation.

The cutting tool used in milling operation is called a milling cutter, which consists of multiple edges called teeth. The machine tool that performs the milling operations by producing required relative motion between workpiece and tool is called milling machine. It provides the required relative motion under very controlled conditions.

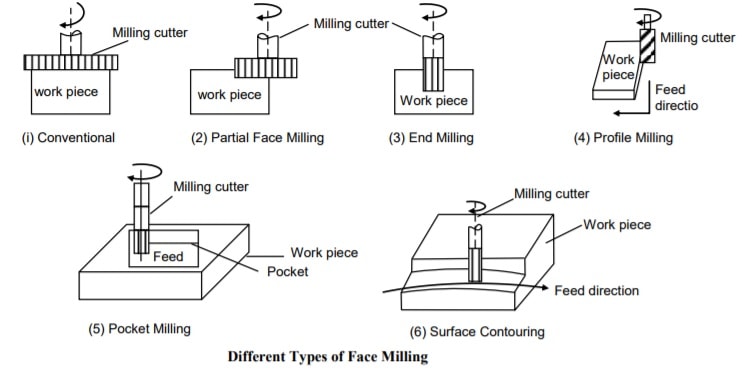

Face Milling Milling

In the operation of face milling, the axis of the milling cutter remains perpendicular to the surface being milled. In this case cutting action is done by cutting edges of both sides (end and outside) periphery of the milling cutter.

Conventional Face Milling

In this case diameter of the milling cutter is greater than the width of the workpiece. The milling cutter remains overhanging on both sides of the workpiece.

Partial Face Milling

In this case the milling cutter overhangs on the workpiece on one side only.

End Milling

In case of end milling thin (low diameter) cutter is used as compared to workpiece width. It is used to make a slot in the workpiece.

Read more: Face Milling – Different Types Of Face Milling Operations