There is a growing industry for CNC services.

According to The Associated Press:

“According to a new report released by market research organization Facts Factors, the global CNC machine market will reach up to $115 billion by 2026. The group attributes this growth primarily to the increase in CNC automation around the world.

“The market was expected to grow to $80 billion in 2019, and meet a continued annual growth rate (CAGR) of 6% through 2027. Interest in CNC machines and their increased application in key industries led to more automation, which has prompted such growth.

Application of CNC Machines

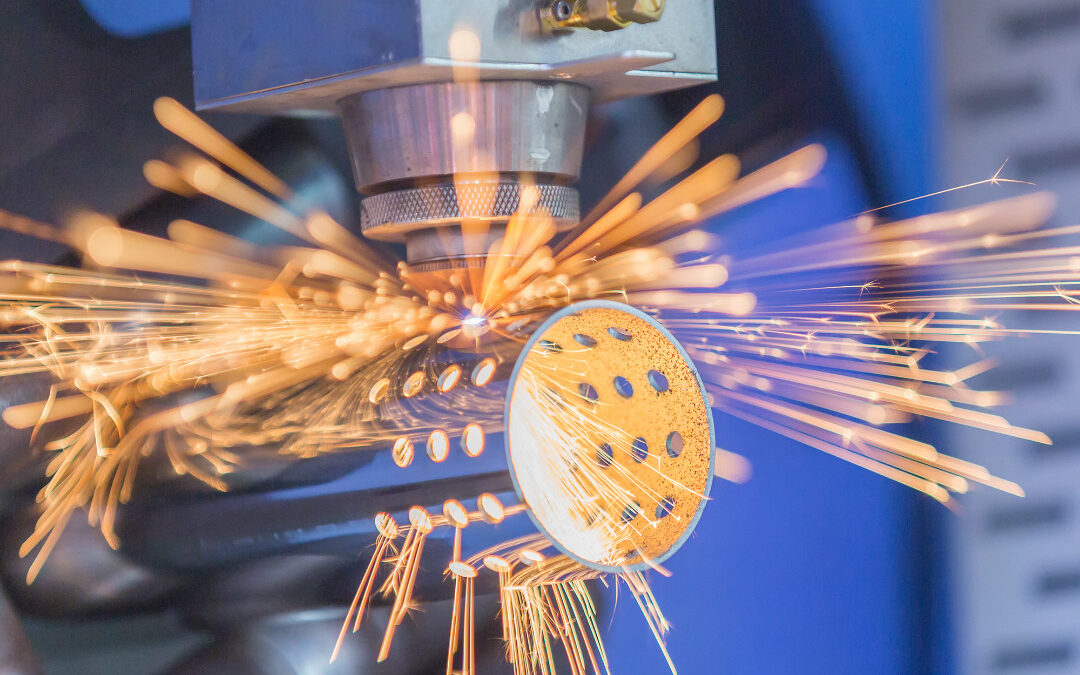

“Computer numerical control (CNC) machines make intricate parts for many industries, including automobile, transportation, healthcare, aerospace, and defense. These computer-driven machines take digital instructions from a Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software to produce a part. With their ability to make quicker, more accurate cuts than manual movement, in any desired shape, CNC machines have become vital manufacturing tools.

The Biggest Industries for CNC Machines

“Companies that require precise, custom parts need CNC machines to make them. They can either use CNC machining in-house or hire CNC machining services —companies dedicated to providing CNC-machine-created parts. The healthcare, aerospace and defense, transportation, automobile, machinery manufacturing, electronics, and petrochemical industries rely the most on CNC machining.

“For example, healthcare companies need personalized products for their patients, like implants and orthotic devices. Aerospace and defense companies need specialized manifolds, bushings, landing gear parts, and other transportation components. The transportation industry needs durable parts that can haul cargo, including brakes, engine parts, and many other parts. CNC machining is especially important to the electronics industry, where companies might require a part as small as 10 micrometers. The petrochemical industry needs CNC machines to produce parts for pipelines, refiners, and rigs as well.

“The application of CNC machines is widespread. The industries with the greatest demand for CNC machine parts, however, are automobile and machinery manufacturing. These two industries have helped boost CNC market growth.

Interest in CNC Machines Has Grown

“CNC machines are popular because they can be used consistently, with little maintenance. It’s also easy to progress CNC machines, just by refining the CAM or CAD software they’re running with. These machines also don’t require as highly skilled workers to operate as manual lathes or milling machines would need.

Why has the market grown?

“According to the Facts Factors report, CNC automation and technological advancements are the key factors that have propelled market growth. They’re also predictors for future growth. Other trends that have shifted the CNC machine market include:

“Demand for solid carbide tools: Solid carbide tools are more durable, retaining their hardness at high machining temperatures and reducing machining cycle time.

Need for smaller machines with more competences: With more mixed-use factories and stores popping up, floor space is at a premium, and smaller machines that can do better work are more valuable.

“Commercial interest in compact CNC machines: More and more, large businesses are using CNC machines for more than cutting and need compact machines to do drilling, deformation, and turning operations.

Which factors will drive future growth?

“The CNC machine market will keep expanding as productivity rises. The automotive and other industries increasingly demand precision and accuracy, while maintaining efficiency and time effectiveness. The market will also grow thanks to government initiatives such as “Made in China 2025” and “Make in India” that foster domestic development of a CNC market. These particular programs will help bolster the market in the Asia Pacific region.

What could inhibit growth?

“The Fact Factors analysis points to the high cost of CNC machines as a potential limiting factor. After calculating the cost of the machine, plus labor and materials, the price tag may be out of reach for some companies.

Breaking Down the CNC Machine Market

“Of the major industries that segment the CNC machine market, machinery manufacturing and automobiles held most of the market share in 2019. Companies in the automotive industry need parts at a high volume and in a short amount of time. CNC machines can meet that need. The report predicts that machinery manufacturing and automobiles will continue to propel growth and advancement in CNC machines in the next six years.

Regional growth

“Regionally, the highest market share of CNC machines was the Asia Pacific in 2019. The analysts also project that the Southeast Asian region will take more market share in the coming years, with rising demand from China, Japan, and India. Europe is another region that should grow its global share of the CNC market in the next six years as well.

Categories of CNC machines

“In addition to segment analysis by application (machinery manufacturing, automobile, etc.), the authors of the Fact Factors report also break down the CNC machine market by type. The six types are lathe, milling, grinding machine, welding, and winding. The CNC lathe category generated the most revenue due to the increasing demand for machines with multiaxis variants. Before 2026, the CNC milling category will grow the most, according to the analysts, because these machines are the most cost-effective to operate.

Biggest Players in the CNC Machine Market

“The Facts Factors analysts consider these companies as some of the top players in the global CNC machine market:

“Bosch Rexroth AG

“Dalian Machine Tool Group Corporation (DMTG)

“Fagor Automation

“FANUC Corporation

“HAAS Automation, Inc.

“Heidenhain Corporation

“Hurco Companies, Inc.

“Mitsubishi Electric Corporation

“Okuma Corporation

“Sandvik AB

“Soft Servo Systems Inc.

“The biggest companies in this market don’t make up a static list, however. Constant mergers, acquisitions, partnerships, and collaboration characterize the CNC machine market. These companies understand that growing a product portfolio is the priority, and if it takes a partnership with a competitor to get it done, so be it.

“The CNC machine market has developed considerably in the last several years, and will continue to shift and expand in the years to come. Although CNC machining is still costly, it may become more common in industries other than healthcare, electronics, automobiles, and its other mainstays.

“This content has been published by Doug Walker Consulting, LLC company. The WiredRelease News Department was not involved in the creation of this content. For press release service enquiry, please reach us at contact@wiredrelease.com.”