Today’s medical instruments have to meet many regulations and standards for sterilisation, biocompatibility, precision, and mechanical quality. It is no wonder that almost any medical practice and institution outsources production of its tools and equipment.

But the monopoly of the centralised manufacturing plant is coming to an end; the future factory is digital and distributed.

Many pioneering, digitally enabled surgeons house one or more 3D printers in their department for pre-surgery planning, educational models, prostheses, and guide parts.

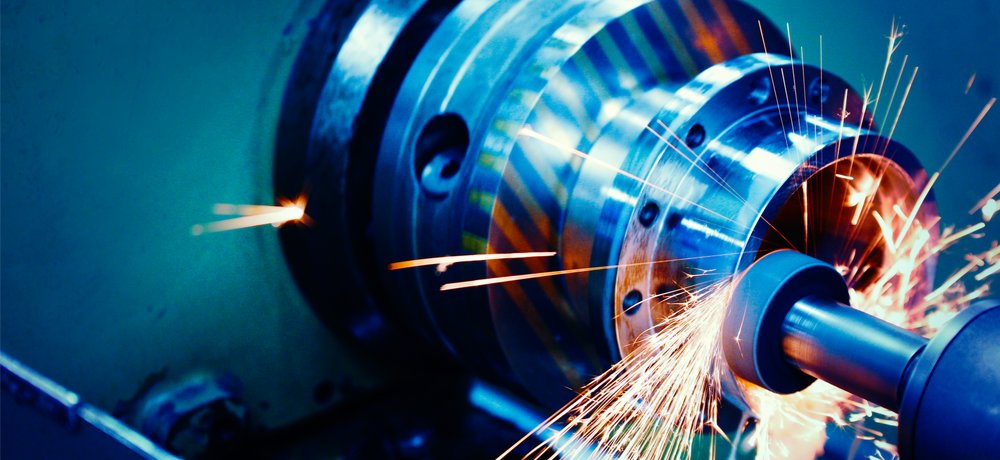

CNC machinery is comparable to a 3D printer, except instead of an extruder there is a spindle with a toolhead that cuts material out of a solid block. The process is equally data-driven with 3D models or scans as input. So the days where hospitals adopt CNC fabrication services are not far off.

- What are the benefits of a local medical CNC minifactory?

- The ability to produce instruments custom to a group of patients.

- Rapidly improving on designs — change the 3D model and instantly produce a new batch.

- Lightweight parts.

- Micromachining parts with feature sizes under 50 microns: stents, catheters, miniature screws, tubes, pacemaker parts, and drug delivery systems.

- A variety of available materials: AISI 316L surgical steel, titanium alloy, cobalt-chrome, and PEEK polymer.

- No fixed tooling investments compared to injection moulding.

- Enormous cost savings.

These cost savings extend to:

Instruments like surgical scissors, biopsy tubes, vial racks, blade handles, saws, forceps, clamps, implant holders, spacers, and plate benders.

Replacement parts for ultrasound, CT, HR monitoring, MRI, artificial respiration, or X-ray equipment: switches, buttons, levers, monitor housings, and UI panels.

Custom lighting fixtures or furniture parts.

If it sounds like vast expertise is needed for complex CNC work, this is true. But with the latest open-source software integrations, the technology has become more accessible than ever for the digitally savvy.

And with the latest state-of-the-art technology, such as artificial intelligence and robotisation, the machines are getting smarter, faster, more precise, and increasingly versatile.

But the development of CNC has come a long way. In the 1800s, weaving looms were geared up to perform complex, data-driven work using punched cards. The same method was used for the first true CNC machine at MIT, enabling them to produce helicopter blades based on computer-calculated airfoil coordinates in the 1940s.

Read more: The quiet history and sudden surge of CNC machining