In the enlightening article “The CNC Machining Process” from IQS Directory, the commitment to precision in CNC machining takes center stage. The CNC machining process, an electromechanical marvel, involves manipulating tools around three to five axes with unparalleled precision, cutting away excess material to craft intricate parts and components. Initial designs are meticulously crafted in CAD, translated into CNC codes that serve as programmed instructions for the CNC machine’s tools.

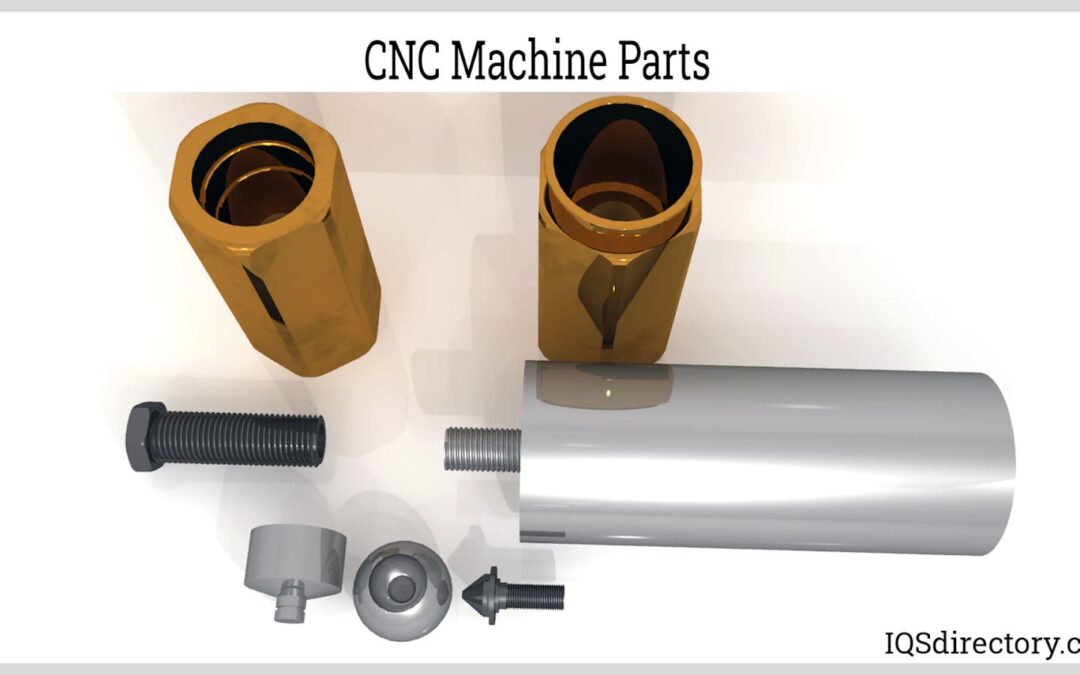

Specializing in achieving cutting-edge quality on turned components, our expertise caters to diverse applications that demand both vertical and horizontal machining. The multitasking prowess of CNC machines enables the seamless completion of components or parts in a single operation, ensuring efficiency and ease. The spectrum of applications handled by CNC machines spans bushings, collars, fasteners, fittings, inserts, machined components, machined washers, pins, nuts, spacers, spindles, standoffs, drive shafts, and splined shafts, among others.

Chapter Two of the article delves deeper into the logical and rational process of CNC machining, emphasizing the meticulous planning required for efficient part production. The computer-controlled machines, guided by two or three-dimensional renderings, execute each operation precisely according to design parameters.

Crucial to the success of CNC manufacturing is the initial programming, where software is coded with precise instructions, ensuring the machine operates within its limitations. Emphasizing careful development of programmed instructions, our aim is to prevent errors and minimize production downtime.

Click here to learn more about Toolcraft Corp’s capabilities.

Photo and article with all rights reserved, courtesy of iqsdirectory.com