In the enlightening article “Expanding Beyond Legacy Tapping Products” by SME, we gain insight into Tapmatic Corp., a family-owned enterprise currently in its third generation of leadership. Since its inception in 1952, Tapmatic Corp. of Post Falls, Idaho, has been renowned for its line of tapping attachments and tap holders, including the notable self-reversing tapping heads gracing machining centers and drill presses. Over the years, their product range has expanded and evolved, showcasing their commitment to excellence.

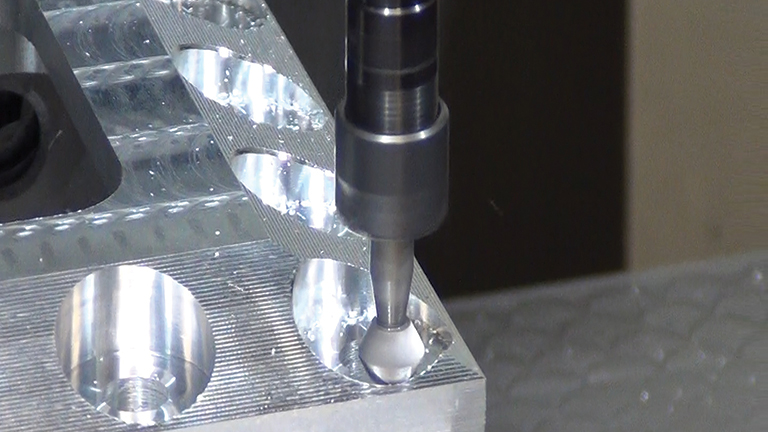

One of the latest additions to their lineup is the DeBurr-Z, a deburring toolholder designed for use in CNC machining centers. Tapmatic President Mark Johnson explains that the DeBurr-Z offers a versatile approach by floating in the Z-axis. It operates in compression for deburring the top edges of a workpiece and extends for deburring the underside. Operators can also fine-tune the force settings, making it adaptable to various materials and cut depths. The DeBurr-Z readily accepts different burrs and chamfer tools, enhancing its utility.

Deburring on a CNC machine tool offers significant advantages over manual methods, providing consistent results, even with less-defined edges such as those found in castings or cross-hole applications. Importantly, it liberates operators to engage in more critical tasks.

Tapmatic Corp. has also ventured into a marking tool line designed for CNC lathes, machining centers, and manual machines. The ScribeWriter Force II, for instance, utilizes a carbide stylus to mark materials up to 62 HRC and accommodates axial surface variations of 5 mm. With an adjustable force setting, it operates without spindle rotation but features coolant-through capabilities. For rotating applications, the TapWriter, a dot peen marking tool, delivers impressive performance, generating 80+ characters per minute in a wide range of materials, including aerospace-grade steel.

Moreover, Tapmatic has adapted to the growing use of high-pressure through-tool coolant by redesigning their RCT-series CNC tapping attachments with a “dual-seal” design, preventing leakage within the attachment body. For synchronous tapping, their heads, such as the SynchroFlex II Synchronous Feed Tap Holder, provide a small amount of axial float, boosting tap life and thread quality. Rigid tapping applications have further bolstered their reputation, making the SynchroFlex II their most sought-after product.

Click here to learn more about Toolcraft Corp’s capabilities and products.

Photo and article with all rights reserved, courtesy of sme.org