Introduction

Milling machines can be used to perform a wide variety of machining operations. While milling machines can be used to perform holemaking and specialized machining operations, they usually perform tasks that fall into one of these three categories: face milling, peripheral milling, and end milling. Let’s look at each of these in a little more detail.

Face Milling

In face milling the cutter is oriented perpendicular to the surface being cut. Face milling is used to create a broad, flat surface on a workpiece. Face mills often have a large diameter and many cutting teeth, however face milling can be done with a tool called a “fly cutter” that has a single cutting surface.

Peripheral Milling

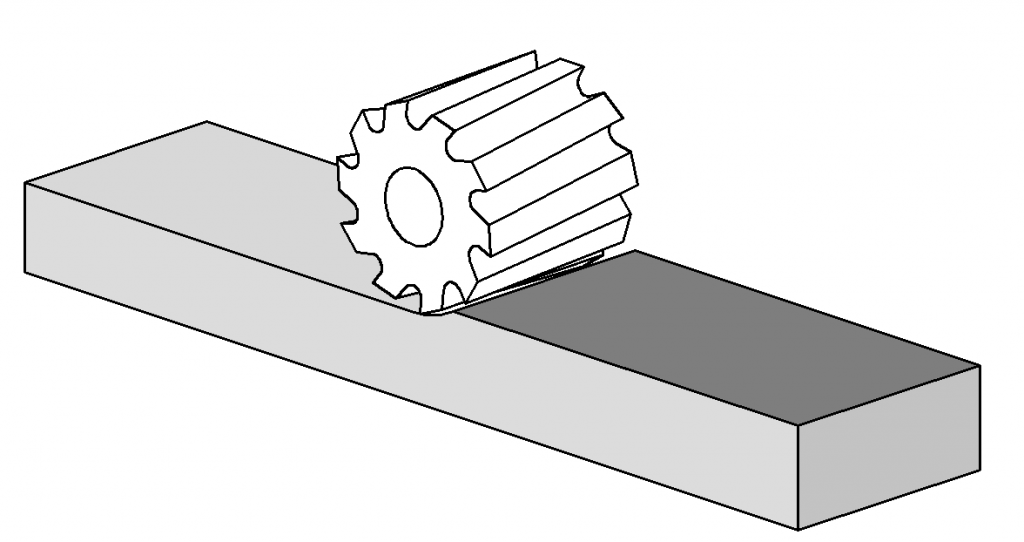

Peripheral milling is performed with the circumference of a round tool. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations.

Slab milling is similar to face milling in that it removes material to make the surface of a workpiece flat and or to reduce the overall thickness of a part.

Read more: MILLING OPERATIONS