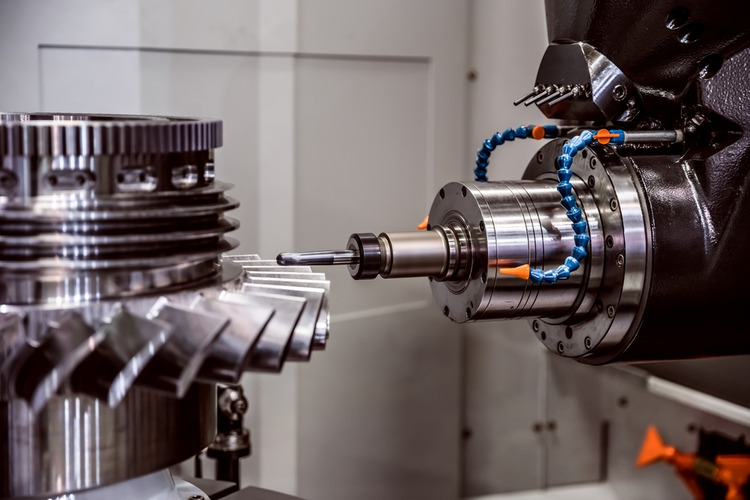

CNC milling is an expensive process. Doing and redoing any operation can seriously disrupt your budget.

Identifying the design and development factors leading to high CNC costs is key. Equipped with the right insights, entrepreneurs can then adjust these factors, minimize their use, and eliminate any production-heavy aspects in production stage. In addition, some of the most common cost-increasing factors may include

Reduce nonrecurring engineering costs (NRE) — one-time costs for researching, designing, developing, and testing new products — wherever possible.

Avoid features involving nonstandard fixturing (soft jaws, sine bars, etc.). Setting each fixture requires a separate setup and CAM program.

Bulk buying is another smart way to compensate for unit expenses.

Consider outsourcing the CNC machined parts of your business to other companies.

Have you considered outsourcing part manufacturing and fully assembled products?

One way to achieve this goal is to outsource the CNC machined parts of your business to other companies. There are some powerful benefits associated with production outsourcing whether you are running a small, medium or large company. If you want to expand your business scope, you must maintain the lowest operating costs and maximize the return on profit.

Read more Minimize CNC Milling Cost