In the world of manufacturing, precision is not just a goal; it’s a necessity. As industries evolve, the demand for accuracy in component assembly grows exponentially, particularly in sectors highlighted by ToolCraft’s expertise, where the margin for error is minimal. This is where Custom True Position Gages, such as those offered by ToolCraft, play a pivotal role.

True Position is a fundamental concept in metrology that defines the exactness of a feature’s location on a manufactured part, relative to its intended design. The challenge, however, lies in the complex nature of modern assemblies where even the minutest deviation can lead to significant errors, potentially compromising the functionality of the final product. Traditional measurement tools often fall short in addressing these challenges, necessitating a more sophisticated approach.

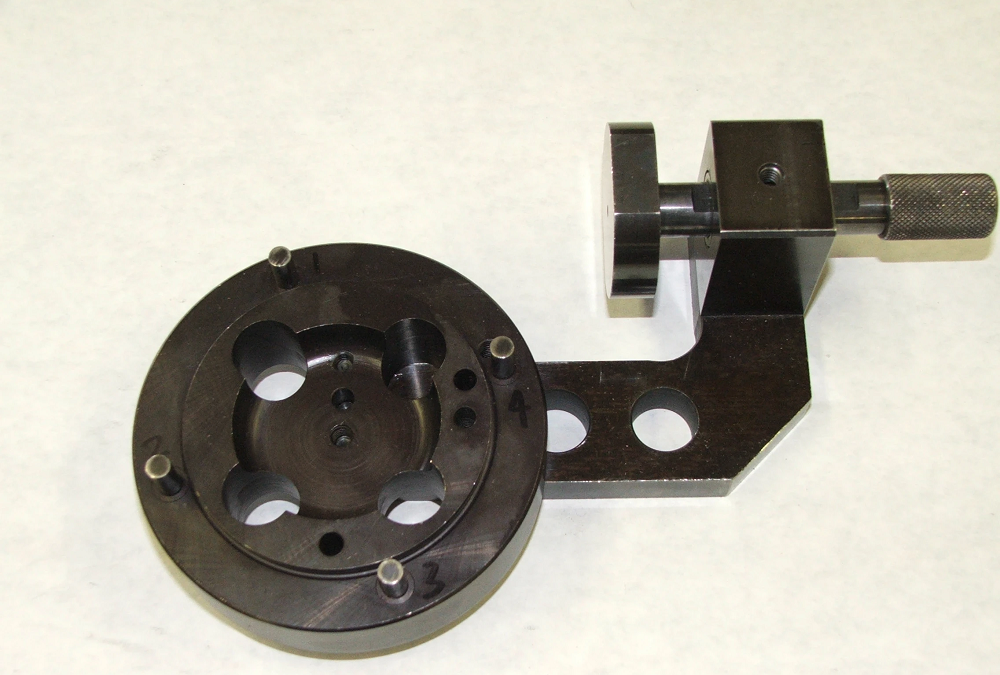

Enter Custom True Position Gages by ToolCraft. These precision instruments are tailor-made to fit the unique specifications of each part they measure, ensuring unparalleled accuracy. By taking into account the specific tolerances, materials, and geometries involved, ToolCraft’s gages provide a direct, reliable method to verify part conformity to design specifications. This level of customization is crucial for industries where the margin for error is virtually zero.

Moreover, the use of these custom gages streamlines the quality control process, significantly reducing inspection time and, by extension, manufacturing lead times. This efficiency not only boosts productivity but also enhances the overall reliability of the manufacturing process. In an era where precision is paramount, ToolCraft’s Custom True Position Gages stand out as essential tools for manufacturers aiming to maintain accuracy in complex assemblies.

By integrating these specialized gages into their quality assurance protocols, manufacturers can achieve a higher standard of precision, ensuring that each component fits perfectly within its intended design. ToolCraft’s commitment to precision and customization exemplifies the art of manufacturing accuracy, setting a new benchmark for quality and reliability in the industry.