As elucidated in the article “Face Milling – Different Types Of Face Milling Operations” from LearnMech, machining operations play a pivotal role in manufacturing processes, and milling is no exception. Milling involves the use of a milling machine, where a rotating cylindrical tool with multiple cutting edges is employed to shape the workpiece. It recognizes the significance of milling operations in achieving precise outcomes.

Face milling, a specific milling technique, entails the milling cutter’s axis remaining perpendicular to the workpiece’s surface. During this operation, cutting occurs on both the end and outside periphery of the milling cutter, ensuring a comprehensive machining process.

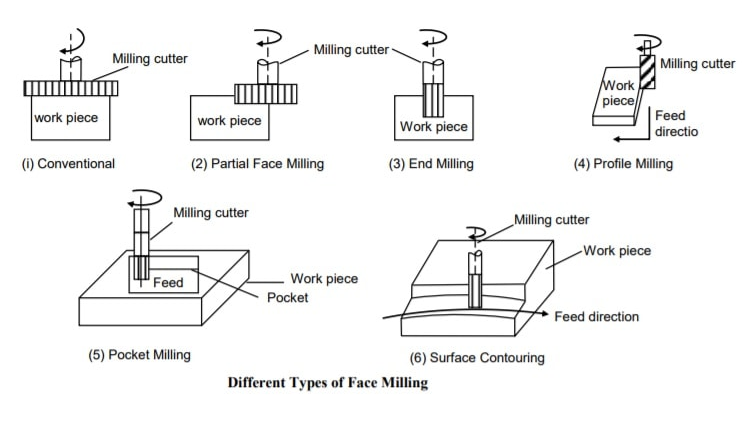

Various face milling methods, including:

- Conventional Face Milling: Utilizing milling cutters with a diameter greater than the workpiece’s width.

- Partial Face Milling: Precision-focused milling with overhang limited to one side.

- End Milling: Employing thin, low-diameter cutters to create slots in workpieces.

- Profile Milling: Crafting flat part peripheries with precision.

- Pocket Milling: Creating shallow pockets on workpiece surfaces.

For more comprehensive insights into Toolcraft Corp’s capabilities follow this link.

Photo and article with all rights reserved, courtesy of learnmech.com