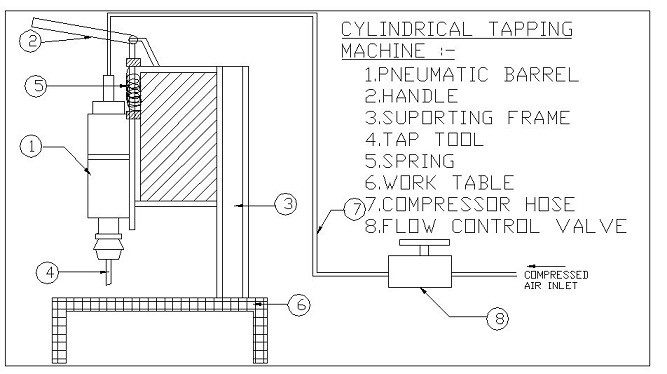

Takes a leap into innovation with the design and fabrication of a cutting-edge pneumatically operated tapping machine. This revolutionary device, powered by compressed air, comprises essential components like the barrel, shaft, bearings, and couplings, demonstrating the company’s commitment to advancing technology in the field.

The project’s primary goal is to create a portable and cost-effective solution for various operations, making it an ideal choice for industries with a focus on minimizing production costs. The tapping machine operates by directing high-pressure compressed air onto a fan, initiating rotation. This rotational energy is then transmitted to the machining head through a shaft, facilitating precise tapping operations.

The introduction to the project emphasizes the practical application of theoretical concepts, highlighting the importance of practical experience in the learning process. Recognizing the significance of minimizing production costs for industry sustainability and addresses this need with the creation of a pneumatically operated cylindrical tapping machine.

The device finds diverse applications across industries, particularly in assembly sections and automobile shops. Its versatility shines through as it performs various operations such as drilling, boring, reaming, grinding, and even functions as a screwdriver for nuts and bolts. The control unit allows for precise adjustment of air pressure, enabling efficient and customized operations.

Click here to learn more about Toolcraft Corp’s capabilities.

Photo and article with all rights reserved, courtesy of learnmech.com