Summary: Facing challenges with a modified 50-year-old machine, a tire manufacturer in NE Indiana lacked updated documentation. Toolcraft, LLC meticulously reverse engineered the machine, producing over 90 precise blueprints. These drawings now allow the manufacturer to efficiently maintain and order parts for the machine, ensuring its ongoing operation.

Industry: Automotive

Process: Reverse Engineering, Design, Blueprints

Category: Machine Reverse Engineering

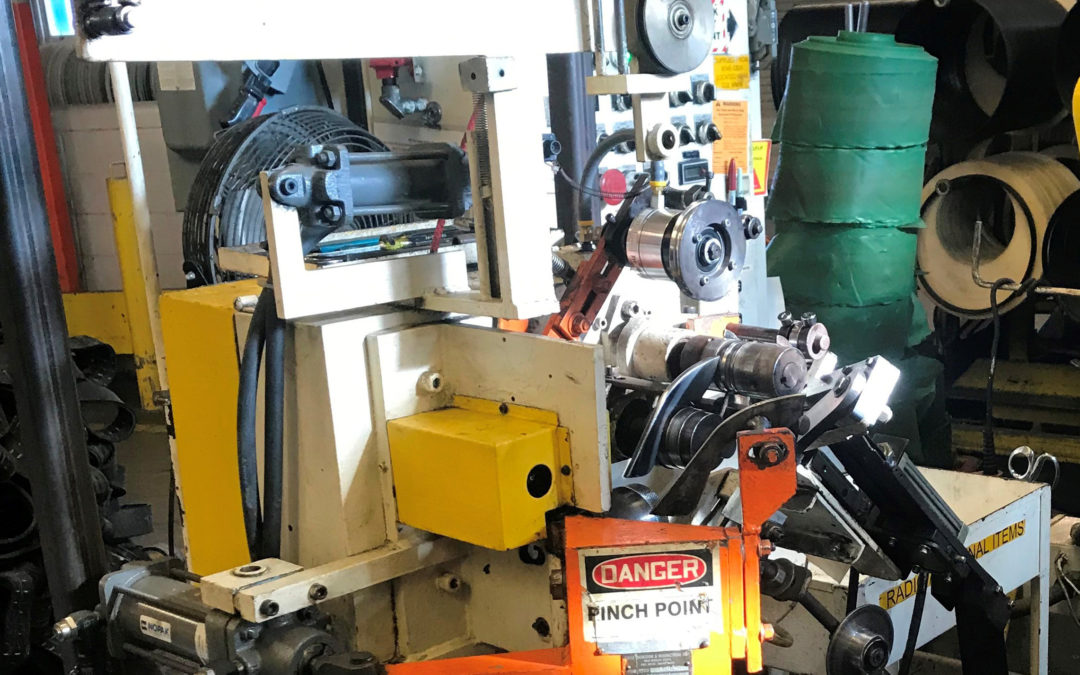

In the heart of NE Indiana, a tire manufacturer faced a challenge: they owned a vital 50-year-old machine that had been modified numerous times over the years. But without up-to-date documentation, maintaining and repairing this machine was becoming a considerable hurdle. They needed an accurate representation of the machine’s current state to ensure its longevity.

Toolcraft, LLC, with our expertise in precision tooling, provided the solution. Our team took the initiative to bring the machine into our workshop. Over a meticulous process, we reverse engineered each component, carefully documenting every alteration and modification the machine had seen over its half-century of service. This intensive examination culminated in the creation of over 90 detailed blueprints.

The blueprints were then organized and presented in a binder, making it easy for the tire manufacturer’s maintenance team to reference. Now, when the machine needs repairs or parts replaced, the manufacturer has a clear and accurate guide to consult, ensuring that the machine continues to operate at peak efficiency.