Into the realm of precision machining with a comprehensive exploration of surface grinding machines, the conventional finish machining process widely acknowledged for producing impeccable surface finishes on components.

At the heart of this process lies the grinding wheel, where abrasive particles act as singular cutting tools, intricately removing material from the workpiece. The cubical or rectangular shape of these abrasive particles shapes the resulting chip, creating an approximate triangular cross-section.

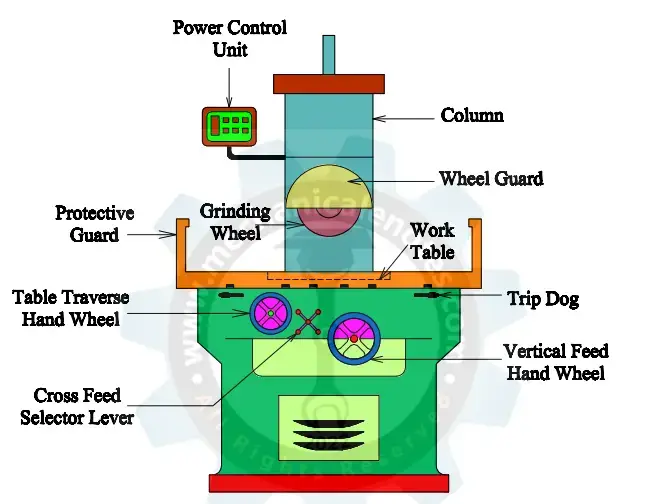

Surface Grinding Machine:

A surface grinding machine is a powerful tool in which a grinding wheel serves as a cutting tool, meticulously removing material from the workpiece’s surface. This abrasive machining process employs abrasives strategically positioned on the grinding wheel’s surface and corners, ensuring a finishing process of unparalleled accuracy.

In this intricate dance of precision, each abrasive particle functions as a single-point cutting tool. The grinding wheel, laden with these abrasives, transforms into a multi-point cutting tool, elevating the precision of the finishing process.

The grinding process stands as a widely accepted finishing operation, renowned for its remarkable material removal capacity, generating minute chips ranging from 0.25 to 0.5 mm.

Click here to learn more about Toolcraft Corp’s capabilities.

Photo and article with all rights reserved, courtesy of mechanicalenotes.com