Over the past few years, CNC machining services have become a vital part of the modern manufacturing world. They offer a wide range of benefits, including efficiency, scalability and enhanced personal safety.

But what is CNC machining, exactly? What are the various types? And more so, what benefits does it offer? This post will cover everything you need about CNC machining, starting with the basics.

What is CNC Machining?

CNC (Computer Numerical Controlled) machining refers to the automation of the manufacturing process through the use of pre-programmed software and code to control the movement of production equipment. It is commonly applied in the mass production of metal and plastic parts. But how do CNC machines works?

CNC machining services use machines that are fully automated – all they need to perform their function is digital files (programs and codes) with instructions on completing a given task.

The manufacturing process requires a wide range of tools to finish the production of a particular part. Switching between these tools in manual machining can be relatively tiresome and monotonous.

Luckily, with a CNC machine, machinists can create digital tool libraries that work hand in hand with physical equipment.

With these pre-programmed instructions, production machinery can automatically switch tools, increasing the efficiency of the manufacturing process.

The CNC machining process starts with the creation of a computer-aided design (CAD) of the required part. The next step is translating the design to G-code and performing test runs to ensure proper positioning and performance.

Types of CNC Machines

There are various types of CNC machines, categorised based on the work they do.

Here are the top 3 most common types of CNC machines:

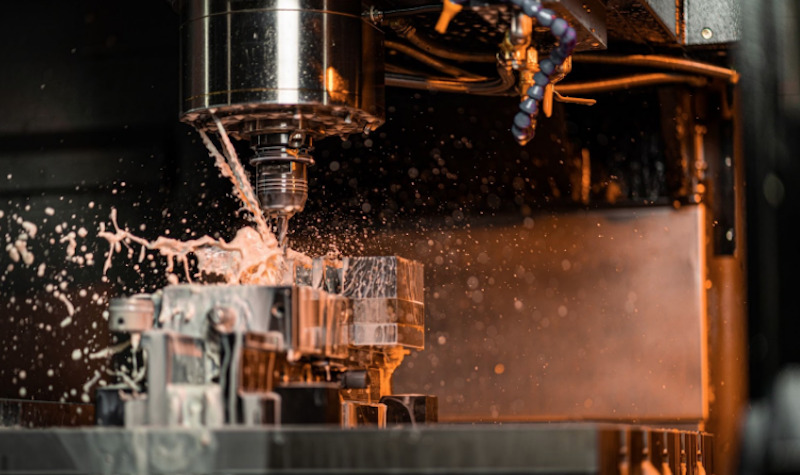

CNC Milling Machines

CNC milling machines are designed to hold raw materials in place while rotating cutting tools to make shapes and cuts. Machinists use these precision machines to develop a wide range of features, including;

- Face-milled features (such as flat surfaces and cavities)

- Peripheral milled features (such as threads and slots)

Read more: What are CNC machining services and what are they useful for?